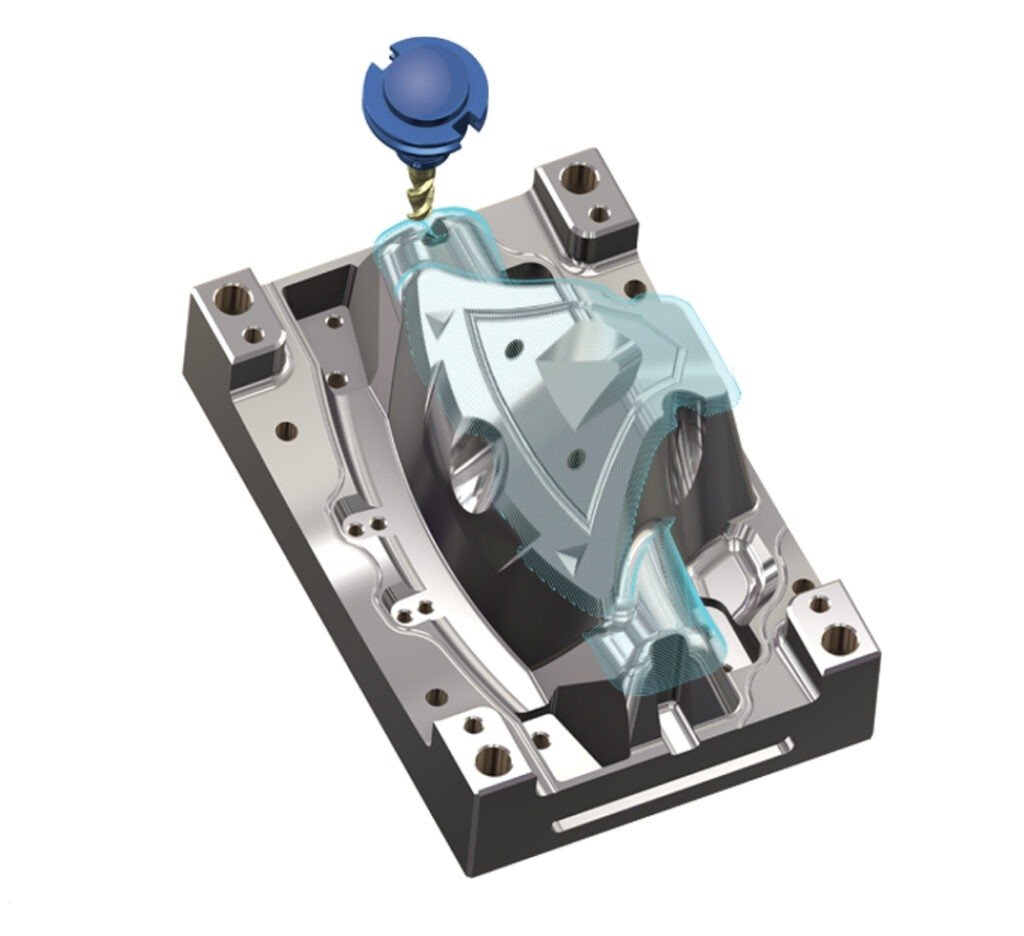

What is Moldex3D Plastic Molding

The leading true-3D molding simulation software can be applied in a wide range of plastic molding processes. We can predict potential manufacturing defects, validates part/mold design, lowers mold development costs, evaluates manufacturability, shortens time-to-market, and greatly increases business value.

- One single platform to run all powerful Moldex3D simulations

- Integrated workflow to ensure accurate meshing and modeling

- Support multiple processes by applications. Check out our solution

Why You Need Moldex3D

- Shorten cycle time and time-to-market

- Reduce number of mold trials and manufacturing costs

- Increase revenue and ROI

- Minimize product defects and extend mold life

Flow

- Predict melt front and flow patterns

- Optimize gate locations and designs

- Diagnose short shots, air traps, weld lines, flow imbalance, and more

- Simulate multi-component interaction

Pack

- Evaluate gate-freeze time

- Avoid sink mark or flash

- Optimize packing profile

Cool

- Improve cooling efficiency and reduce cooling cycle

- Predict hot spots

- Support multiple cooling / heating system, conformal cooling and CFD

Warp

- Foresee final part shape

- Identify warpage causes

- Support residual stress, anisotropic, in-mold constraint effect analysis

CAD & Mesh

- CAD conversion & repair tool

- Modeling Capability

- Powerful automatic & customized meshing technology

Advanced Analysis

- Machine Response & Plastification

- Advanced Hot Runner (AHR)

- Stress & Viscoelasticity (VE)

- Optics

- In-Mold Decoration (IMD)

Computing

- Parallel Processing (PP)

- Remote computing

- Windows and Linux HPC platform supported

- Cloud-Connect: Cloud computing HPC toolkit

Automation

- Report Wizard

- Expert (DOE)

- Moldex3D API

Solutions by Industry

Solutions by Application

Injection Molding

Foaming

Others

Moldex3D Solution Add-on

Expert (DOE)

helps users evaluate the optimal process conditions, such as packing time, cooling time, or mold temperature. Moldex3D Expert creates analysis variations and provides graphical summaries automatically.

SYNC

brings a simulation-driven design environment. With its powerful analysis capabilities fully embedded in mainstream CAD software, CAD users can synchronize design changes and quickly validate plastic designs.

Fiber Reinforced Plastics

Fiber

visualizes fiber orientation and calculates process-induced anisotropic thermo-mechanical properties for long and short fiber-reinforced plastics. Users can predict warpage distribution and evaluate part strength.

FEA Interface

provides a series of FEA Interface modules integrated with industrial leading structural software, including ABAQUS, Ansys, LS-DYNA, Marc, Nastran, and Radioss. Users can export Fiber and Stress analysis results to calculate further structural performance.

Micromechanics Interface

allows users to output more material properties for nonlinear multi-scale material modeling with integration of Digimat and Converse before FEA software.

Advanced Analysis

Stress

provides stress distribution for parts and part inserts. Users can set boundary conditions, such as stress or force, to evaluate the structure quality of plastics and predict potential breakage or deformation.

Viscoelasticity Viscoelasticity (VE)

calculates viscosity and elasticity variations of plastic materials under different temperature conditions. Users can evaluate the effects on molecular orientation, residual stress, warpage, and optical properties.

Advanced Hot Runner

visualizes the filling pattern and temperature distribution of hot runners and moldbase. Users can evaluate the heating efficiency and uniformity to optimize hot runner design.

Molding Processes

Compression Molding (CM)

simulates the compression molding process in which the polymer is squeezed into a preheated mold cavity. Moldex3D helps users check potential defects resulted from heat and pressure, decide appropriate materials, and optimize process conditions.

Injection Compression Molding (ICM)

Simulates the injection compression molding process, generally applied to thin and flat plastics, such as light guide plates or compact discs. Users can observe the compression process over time in cavity and evaluate material properties and process conditions.

Powder Injection Molding (PIM)

visualizes metal or ceramic molding process. Users can observe the fluid flow behavior of the feedstock, consisted of powder and binder, and predict potential defects. You also can evaluate the effects of shear rate and optimize process conditions.

Water-Assisted Injection Molding (WAIM)

visualizes the dynamics of water-assisted injection molding process for hollow plastics. With the visualization of fluid penetration behavior inside the mold cavity, users can define the overflow region and optimize process conditions.

Co-Injection Molding (CoIM)

visualizes the sequential injection molding process of skin and core plastic materials. Users can decide plastic material pair to optimize the combination of two material properties. You also can predict potential breakthrough on part surface.

Bi-Injection Molding (BiIM)

visualizes the molding process of two materials being injected independently into a mold cavity. Users can define material type, set independent filling and packing parameters for each material, and observe the flow rate variation from two melt entrances.

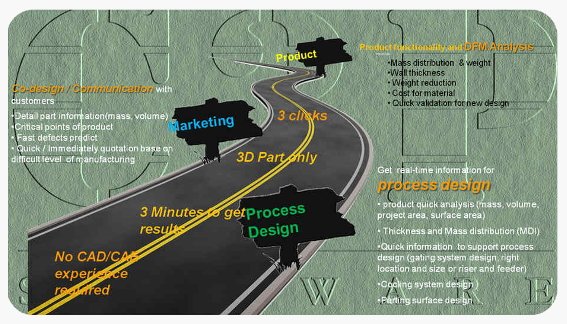

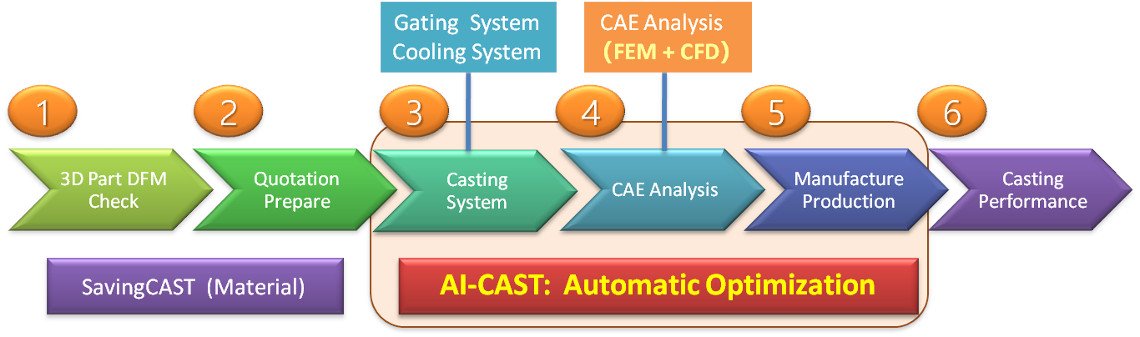

Cast Designer – Integrated KBE & Simulation

CAST-DESIGNER OVERVIEW

C3P Engineering Software International Co., LTD has developed a software namely Cast-Designer, which is specially designed for Casting business. The Cast-Designer software has more than 50 years of industry experience to provide end-to-end solution for foundry industry, ranging from metal charging, DFM analysis, step-by-step guidance in gating system design, advanced thermal, flow, solidification and stress simulations and artificial intelligent based automatic optimization.

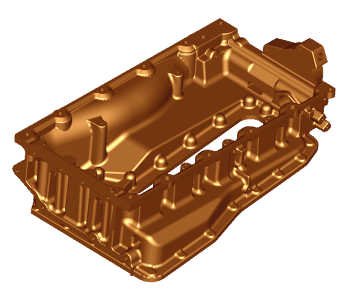

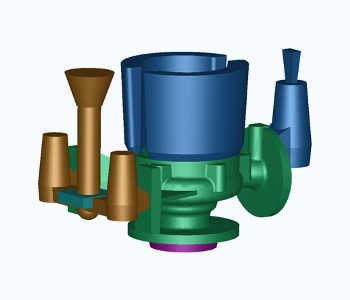

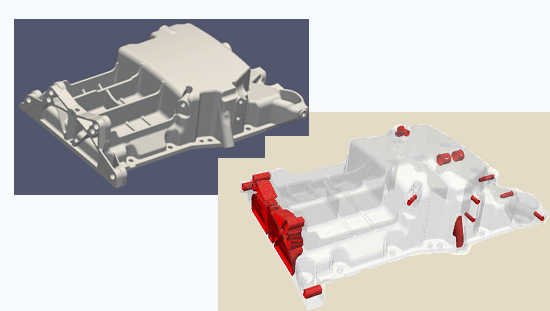

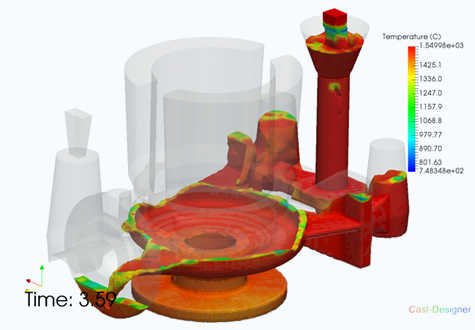

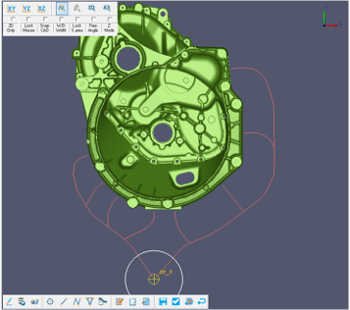

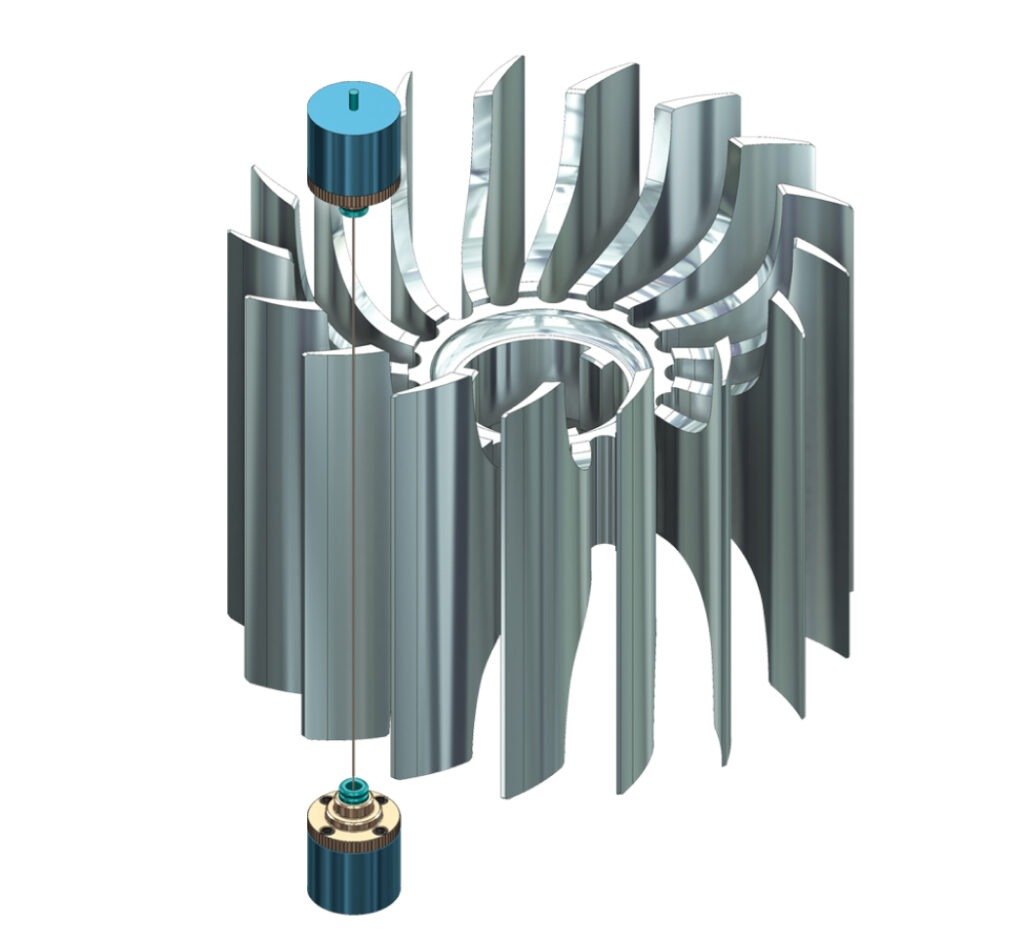

3D Casting part

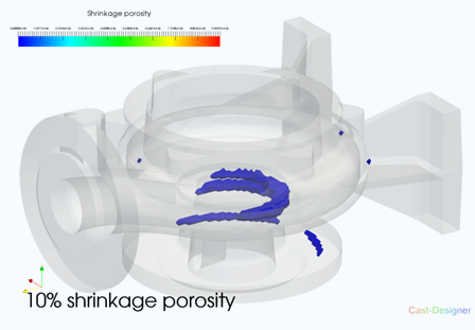

The Cast-Designer software supports all major foundry processes and predicts the casting defects like shrinkage porosity, air entrainments, surface defects, residual stresses, distortions etc. The Software Helps foundry engineers to make right decisions early in the design stage of casting system development and to improve quality & yield ultimately reduce the manufacturing cost. It can also help the industry to achieve the target of 'Time to Market', 'Quality to Market' and remain 'Competitive'.

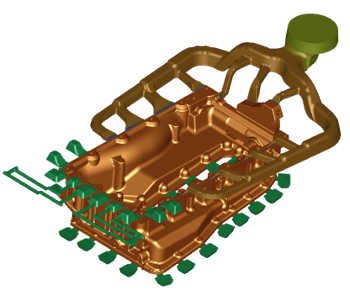

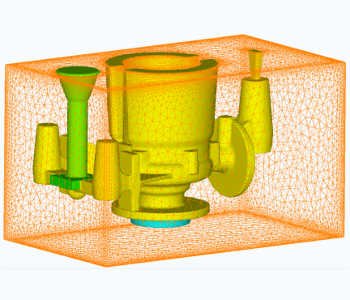

DFM: Part Base Analysis

The DFM (Design for Manufacturing) analysis is the first step for part manufacturing. DFM is the bridge to link the part designer and manufacturing suppliers. Geo-Designer is a powerful Upfront DFM tools for designers and manufacturing engineers with innovative technology. It accelerates the design process for functions, manufacturability, enabling designs to move to production better and faster. If we compared Geo-Designer with other traditional tools, it is found that the Geo - Designer is powerful, flexible, fast and easy to use and provides savings in downstream costs of quality improvement in the design stage.

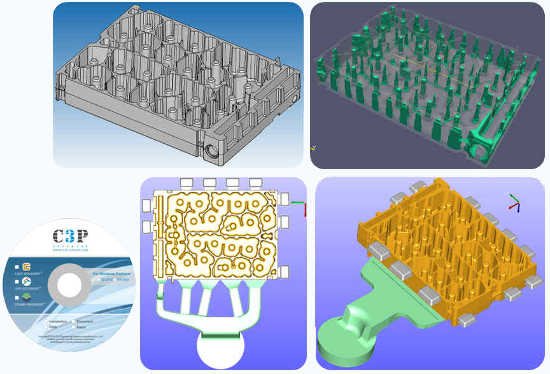

Geo-Designer

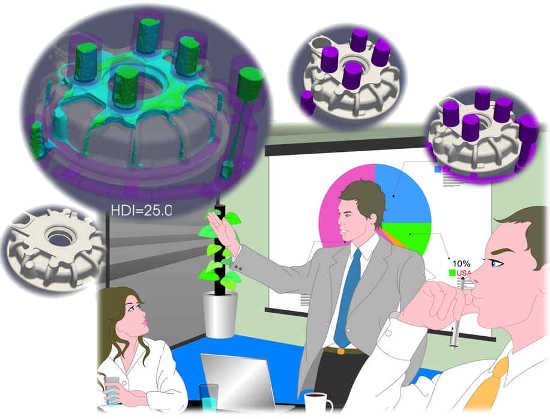

Geo-Designer can bring a very clear benefit to casting part designer and mold supplier, such as MDI(Mass Distribution Index) /HDI (Heat Distribution Index) analysis, slider checking, draft angle and undercut checking, ejection force evaluation, riser and feeder design, cores extraction, cooling system designer, etc.

Geo-Designer can be used for both OEM and supplier companies. With Geo-Designer, the product designer, supplier marketing engineer and process designer could make synchronous design together.

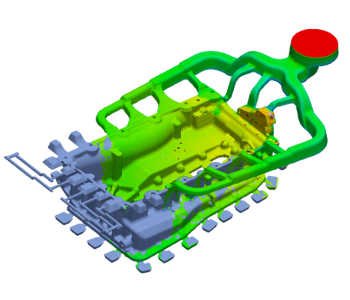

DFM Analysis for Casting Part

Geo-Designer offers a new method to study the part geometry in 3D iso-surface mode with flexible transparency. It is similar to the x-ray and CT method in the industry. Geo-Designer has introduced MDI (Mass Distribution Index) and HDI (Heat Distribution Index) for part analysis and evaluation.

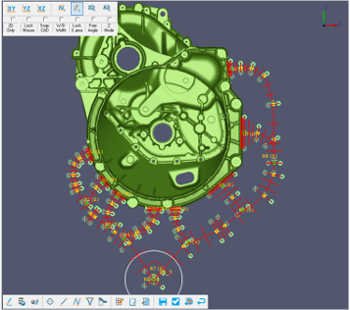

MDI Checking

The MDI (Mass Distribution Index) can be used to check the heavy mass distribution of the casting part, where it is easy to cause the hot spot and shrinkage porosity during the casting process. As a product design engineer, you should try to avoid big MDI on the part.

During the manufacturing phase, the MDI result can be used directly for inner gate design, riser and feeder design, cooling channel layout and hot spot prediction.

Slider checking

For die casting and permanent mold casting, the slider number and complex level are an important factor of the die set cost. Geo-Designer can perform slider checking for casting part to help slider design. Simply define the plug direction or opening direction and the partition plan, then the system will calculate the others. More ever, the surface of ‘Slider Zone’ can be also exported to CAD system in STL file format to guide the slider design in 3D CAD system.

Evaluate the design plan of casting system

The MDI information can also guide the gating system design. For example, the following part is used for a communication device, due to the heavy MDI on the contact shaft, gas entrapment and shrinkage porosity will be existed there, and the gas escapement will break the coating layer in sliver after a couple of months and damage the whole system. The first gating was complex, but cannot solve the gas problem and shrinkage problem, the part yield ratio was only 67.1%. After checking the MDI in Geo-Designer and understanding well of the geometry of the part, then changed the gating system to the later one, and using the 3rd phase pressure to reduce the shrinkage porosity, then the yield ratio of the part has been increased to 92%.

Other analysis functions

The other functions could be provided by Geo-Designer for part analysis, such as

- Ejection force distribution and evaluations

- Draft angle checking and undercut checking

- Fillet radius checking

- Thin wall thickness checking

- General part information, such as mass, volume, project area and thermal modulus

Riser & Feeder design

The powerful HDI analysis of Geo-Designer can help the riser, feeder, insulator sleeve and chill design, specially used for gravity casting. If we compared with other experience formulas and graphic programs, the Geo-Designer approach is more flexible, accurate and easy to use. Since all the experience formulas are very difficult to consider in the 3D geometry, it is usually quite complex.

In HDI calculation, the system will also consider the heat affection of the around media. For example, heat affection by the feeder or riser. It is also possible to consider the different material type, such as the chill to speed up cooling, the insulators to keep the heat and cool down slowly.

Based on the HDI results, the user can design riser and feeder on the thicker zone to compensate the metal shrinkage. The online checking result was very clear, both the component size and location could be designed well by the assistant of the Geo-Designer. More ever, the updated HDI/MDI result can be obtained immediately, just click a button, anything has been updated. So, it is hundreds of times faster than the numerical simulation method. The final design result can be exported to Cast-Designer system or other CAD system in STEP file format.

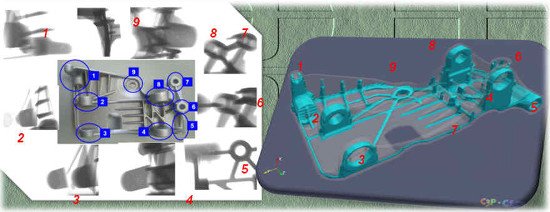

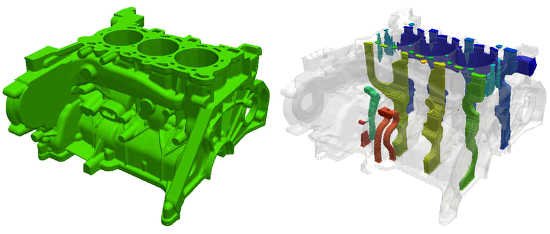

Core design and checking

For complex casting part, such as the engine block, the designer must consider the sand core inside the part, this is very important and with big challenge. The section area and geometry shape of the core must be designed carefully.

With powerful Boolean operation function in mesh base, the Geo-Designer can extract the inner core from the existed casting part easily. Then, the user can analysis the detail sections of the core or export the core surface to another system in STL file format.

The Cast-Designer software is a quick casting design and analysis tool which is based on Upfront Design and Analysis Technology. The core of Upfront Design and Analysis Technology is to allow engineers to conduct fluid flow, heat transfer and solidification analysis with the assistance of combination of expert system and CAE technology. So that it helps engineers to make a Right decision in the early design stage of a project. The Upfront design & analysis technology have already been becoming a very important role in main stream design process.

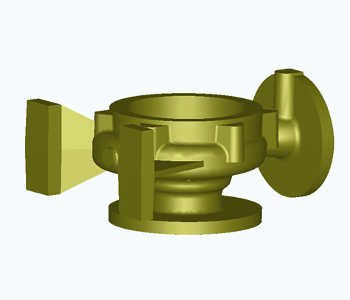

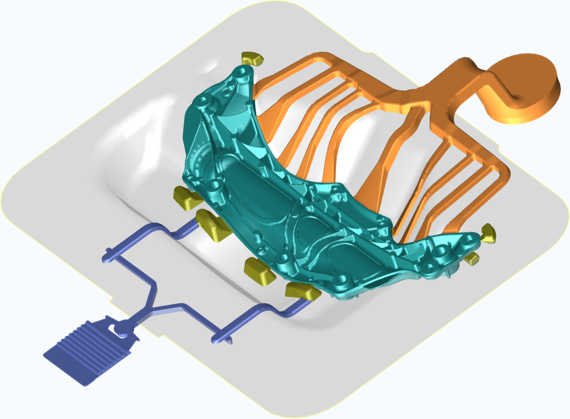

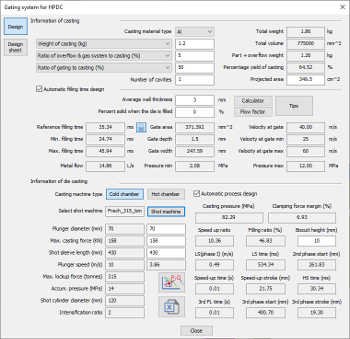

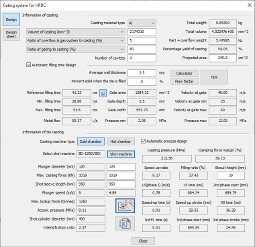

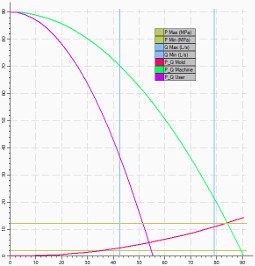

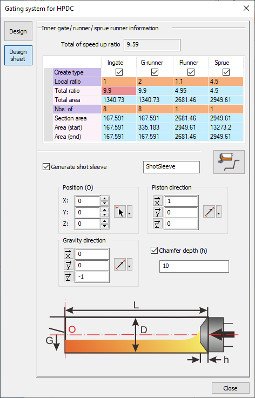

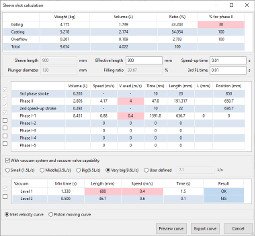

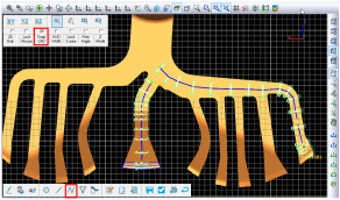

Casting Design: Die Casting

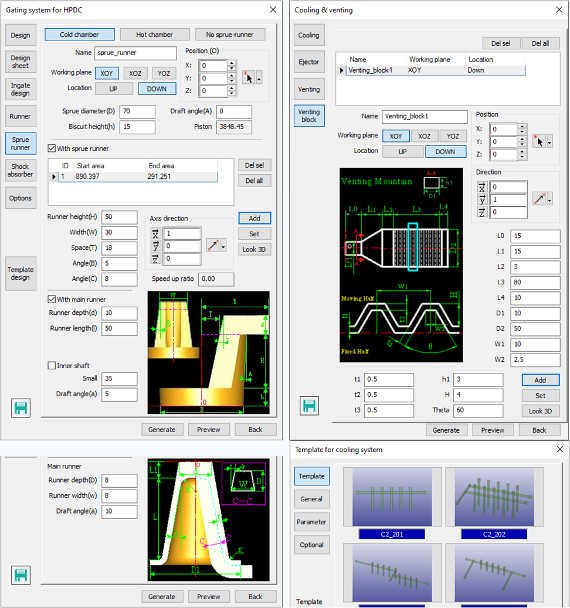

Cast-Designer's Gating Design Advisor is designed with 50 years of industrial experience and NADCA standard recommendations. It provides step-by-step guidance to the user to design an effective gating system, starting from the shot machine selection, inner gate area, runner section, velocity, fill-time, overflow, venting and cooling channels etc.

With Cast-Designer's Automatic Optimizer, this initial gating design could be fully optimized to produce error-free castings.

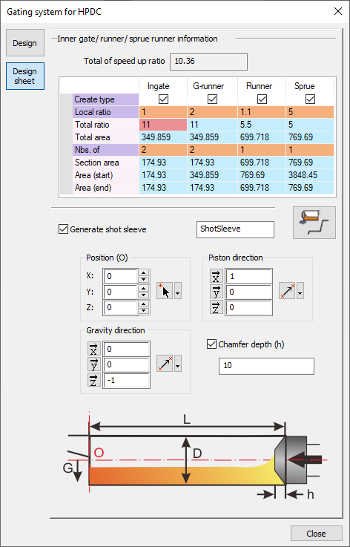

HPDC gating system design

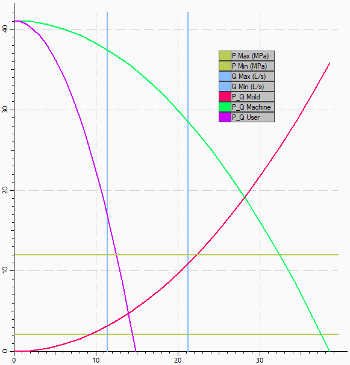

- PQ Graph evaluation of the design

- Provides fill time and required inner gate area

- First phase and Second phase velocity

- Cooling channel calculator

- Overflow requirement calculator

- Sprue runner, venting design tools

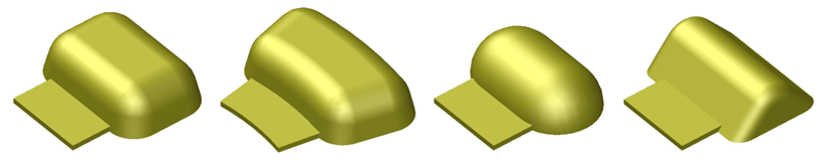

FREE STYLE GATING DESIGN

- Free-Style' gating design tools has intelligence about the standard definition of different runner shapes.

- By simply picking few points on the parting surface a spline created as a projected 3D spline.

- Taking this spline as controlling center line, runner geometry is created in 3D with required draft, rounds etc.

- 3D runner is always created as a swept blend with smooth bends.

- Based on the designed local speed-up ratio, runner section’s start area and end areas are controlled.

- Free design also supports pre-defined template library. The customize tools can help user to make customization in a few clicks.

DESIGN TOOLS FOR HPDC

- Shot Machine Tonnage Calculation Tool: Using user given projected-area of the casting and casting pressure category, this tool provides shot machine tonnage required to manufacture the casting.

- Shot Machine Database: Cast-Designer has a collection of shot machine data. This database can be referred for machine tonnage and for PQ graph analysis.

- Casting Wall Thickness Analysis Tool: A handy tool to find average wall thickness of the casting and thin and thick regions in the casting.

- Casting Zone Analysis: Provides selected region/zone's volume and in-gate sizes for the designed in-gate velocity and fill time. Helps to design uniform filling.

- Shot Sleeve Model Generator and Velocity Curve Generator: CAD models are automatically created with filled, unfilled regions and piston of the shot sleeve. Piston velocity or distance curve can be created and verified for vacuum system and shot-machine's capability.

- Overflow Design Tools : Different standard shapes supported.

- Cooling Calculators and Design Tools : Cooling channels calculator helps designer to arrive at length and size of the cooling channels and design tools to create cooling channels for analysis.

- Venting Calculators and Design Tools : Chill vent designer can create standard design quickly.

REVERSE ENGINEERING OF EXISTING GATING DESIGN

- Special tool for Reverse Engineering of existed gating system from ANY CAD system(CAD, STL, mesh etc.).

- Convert to full parametric gating in few minutes to optimize the design performance.

- 3D runner projection is another useful function to convert the 2D plan runner.

With parametrically designed gating model, it is easy to modify the design for better flow performance results

ABOUT

Mastercam software is a powerful computer-aided design (CAD) and computer-aided manufacturing (CAM) software used for designing and creating parts, products, and toolpaths. It is widely used in the manufacturing industry, specifically in the areas of aerospace, automotive, medical, and energy sectors. In this article, we will discuss Mastercam software in detail, its features, benefits, and applications. What is Mastercam Software? Mastercam is a leading CAD/CAM solution that offers advanced design tools and machining features. In fact, it is a Windows-based software that provides designers and engineers with a comprehensive set of tools to create and manufacture complex parts and products. Mastercam software is developed by CNC Software, Inc., which is headquartered in Tolland, Connecticut, USA. Features of Mastercam Software Mastercam offers several features that make it a popular CAD/CAM software in the industry. Here are some of the most prominent features of Mastercam:

ABOUT CNC Software, Inc.

As an industry leader for more than 35 years, CNC Software takes pride in meeting the demanding needs of our customers by providing excellent products at affordable prices. We adhere to our strategy of combining superior software programming with practical shop floor experience. We have remained at the forefront of CAD/CAM technology by listening to our customers’ needs, being accessible, and most of all, being dedicated to our customers. CNC Software has provided CAD/CAM solutions to more than 250,000 installations worldwide in the moldmaking, automotive, aerospace, and consumer industries.

-

Mill Solutions

Mill SolutionsGive your shop the best possible foundation for fast and efficient milling. From general purpose methods such as optimized pocketing to highly specialized toolpaths like 5-axis turbine cutting, with Mastercam Mill, your parts are produced faster, with greater accuracy, quality, and repeatability.

-

Lathe

LatheOur Lathe CAM programming software gives you a set of tools to turn your parts exactly as you need them. Mastercam Lathe provides easy roughing, grooving, threading, parting, boring, drilling, and finishing routines for increased productivity.

-

Mill-Turn

Mill-TurnMastercam Mill-Turn programming software streamlines high-power multistream machine centers for increased performance and safety. These multitasking CNC machines reduce multiple setups, manual part handling, redundant fixturing, and idle time for improved productivity in manufacturing.

-

Swiss

SwissYou no longer need a separate software package for CNC Swiss machines — something programmers and machinists appreciate. Give your shop the convenience and precision of Mastercam Swiss Machining Solutions for gang-style machines and select gang-turret and B-axis machines.

-

Wire

WireFast, easy, and productive—the way programming should be. Mastercam Wire is a solution for programming CNC Wire EDM machines.

-

Router

RouterWhen you invest in a CNC router machine, you want the right router software driving it to maximize productivity and avoid downtime due to costly errors. Mastercam Router delivers the right tool exactly when you need it.

-

Design

DesignMastercam Design is a computer-aided design solution that simplifies the creation of even the most complex parts with a robust suite of CAD tools. Design is included with Mastercam’s suite of CAM solutions. It is also available as a standalone product.

CNC Programming Software Products

Give your shop the best possible foundation for fast and efficient milling. From general purpose methods such as optimized pocketing to highly specialized toolpaths like 5-axis turbine cutting, with Mastercam Mill, your parts are produced faster, with greater accuracy, quality, and repeatability.

Many of the products we use every day are made with the help of Mastercam Mill. This software delivers a full array of machining strategies and so much more. Mastercam milling solutions can be customized to what your shop needs today and easily scaled to meet your future manufacturing needs.

- A full design package based on a machinists needs including wireframe, surfaces, and solids design

- A wide range of toolpath modules, from industry-leading 2D/3D Dynamic milling strategies to multiaxis and specialized options like Port Expert and Blade Expert

Our lathe cam programming software gives you a set of tools to turn your parts exactly as you need them. Mastercam Lathe provides easy roughing, grooving, threading, parting, boring, drilling, and finishing routines for increased productivity.

Mastercam Lathe also delivers a set of C-axis programming tools, with greatly expanded options when combined with Mastercam Mill, such as face contour and drilling and cross contour and drilling.

- Integrated CAD for CAM provides a powerful set of tools for creating and manipulating wireframe, surfaces, STL, and solids data including MBD information (with select translators).

- Advanced toolpath strategies turn parts with greater efficiency and precision.

Mastercam Mill-Turn programming streamlines high-power multistream machine centers for increased performance and safety. These multitasking CNC machines reduce multiple setups, manual part handling, redundant fixturing, and idle time for improved productivity in manufacturing.

Using Mastercam’s proven milling and lathe toolpaths, this software simplifies the programming process for mill-turn machines with job setups keyed to the exact machine in your shop.

- Optimization, synchronization, and visualization in a single platform.

- Automation to easily manage complex operations between multiple machine data streams.

- Efficient milling, turning, and drilling operations with fewer setups at high speed.

- Program simple lathes in addition to complex machines.

You no longer need a separate software package for CNC Swiss machines — something programmers and machinists appreciate. Give your shop the convenience and precision of Mastercam Swiss Machining Solutions for gang-style machines and select gang-turret and B-axis machines.

Our Swiss Solutions combine Mastercam Mill and Mastercam Lathe, with an optimized post processor to give you a reliable set of tools to program parts for your Swiss machines—exactly how you need them.

- This bundle of technology delivers precision G-code and the flexibility to standardize your shop with a single software package to program a wide variety of Swiss machines.

- Provides enhanced POCO (Pick-Off Cut-Off) strategy.

- Includes multi-stream NC program viewing.

- Customized Swiss posting options allow for more accurate G-code programming.

- Integrated CAD for CAM provides a powerful set of tools for creating and manipulating wireframe, surfaces, STL, and solids data.

Programming in the Lathe product provides easy roughing, grooving, threading, parting, drilling, boring, and tapping. You can also perform milling operations with Mastercam’s proven toolpaths such as Contour, Drill, Dynamic Motion, OptiRough, Pocket, and Project for increased productivity. Mastercam Lathe also delivers a set of C-axis programming, with greatly expanded options when combined with Mastercam Mill, such as face contour and drilling, and cross contour and drilling.

Fast, easy, and productive—the way programming should be. Mastercam Wire is a solution for programming CNC Wire EDM machines.

Mastercam’s suite of 2-axis and 4-axis wirepaths lets you choose the best method for the results you need, with control over the wire motion, angle, entries and exits, and much more. And you get that control in a clear, easy to understand way.

- Full-featured design capabilities support any combination of modeling, from wireframe to surfaces to solid models.

- Automatic lead-in and lead-out strategies, fast, flexible tab creation, and no core cutting make Mastercam Wire a powerful tool for quickly programming parts.

- Intelligent NC programming lets you build a library of machining strategies that automatically adapt to new models.

- Mastercam Wire complements the functionality of other products such as Mastercam Mill and Lathe.

When you invest in a CNC router machine, you want the right router software driving it to maximize productivity and avoid downtime due to costly errors. Mastercam Router delivers the right tool exactly when you need it.

Anyone with a CNC router, from the home hobbyist to professional manufacturers, can appreciate the ease, speed, and reliability of Mastercam Router software. The software delivers industry-proven NC programming for safe and efficient router machining of everything from wood to composite materials.

- From CAD inception to part completion, Mastercam Router is designed as a comprehensive solution for manufacturing productivity.

- Mastercam Router supports features that are unique to CNC routers, including toolpath and geometry nesting, block drill support, aggregate head support, saw cutting support, and full 2- through 5-axis cutting.

Mastercam Design is a computer-aided design solution that simplifies the creation of even the most complex parts with a robust suite of CAD tools. Design is included with Mastercam’s suite of CAM solutions. It is also available as a standalone product.

From fixing flaws in an imported model, to creating fixtures for work holding on a machine-and so much more, this powerful CAD engine includes modeling and prep tools for CAM programmers to get parts on and off machines quickly.

- Comprehensive CAD platform.

- Direct modeling, file import functionality, and model prep.

- CAD for CAM supports production efficiency.

Mastercam for SOLIDWORKS® is an integrated software solution combining the world’s leading CAD with the world’s most widely used CAM.

With this product, you can standardize your database of CAD files with no need to compromise the quality of your NC programming. SOLIDWORKS users gain all of the programming benefits of Mastercam for streamlined productivity. Fast, easy, and accurate — the way manufacturing should be!

- Includes Mastercam’s industry-leading toolpath technology and post processors in the SOLIDWORKS environment.

- Delivers the ease of SOLIDWORKS add-ins such as modeling, assemblies, and drawings with fully associative Mastercam toolpaths.

- Utilize SOLIDWORKS configurations to program an entire family of parts with one click.

Mastercam Mill, Lathe, and Router products include the option to run a corresponding Mastercam for SOLIDWORKS® environment. Standalone licenses of Mastercam for SOLIDWORKS® Mill and Lathe products are also available for purchase.

Mill Solutions

Give your shop the best possible foundation for fast and efficient milling. From general purpose methods such as optimized pocketing to highly specialized toolpaths like 5-axis turbine cutting, with Mastercam Mill, your parts are produced faster, with greater accuracy, quality, and repeatability.

Product Overview

Many of the products we use every day are made with the help of Mastercam Mill. This software delivers a full array of machining strategies and so much more. Mastercam milling solutions can be customized to what your shop needs today and easily scaled to meet your future manufacturing needs.

- A full design package based on a machinist’s needs, including wireframe, surfaces, and solids design

- A wide range of toolpath modules, from industry-leading 2D/3D Dynamic milling strategies to multiaxis and specialized options like Port Expert and Blade Expert

From CAD inception to the creation of a final machined part, Mastercam is designed as a comprehensive solution for manufacturing efficiency.

- Full 3D CAD modeling

- Context-sensitive help available from all dialog boxes

- Powerful Multiaxis cutting

- Easy pocketing, contouring, and drilling

- Intelligent, stock-aware toolpaths

- Robust 3D solids and surface machining

- Complete tool library and custom tool support

Features

Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

Take advantage of innovative profile tools and processes aimed at greater efficiency and higher machining productivity.

Reduce costs and cut programming time with advanced toolpaths like Deburr and Equal Scallop.

Open any CAD file in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Our Mastercam Representatives bring years of practical experience specific to various regions, manufacturing goals, and language requirements worldwide, to ensure that as a Mastercam user, you always have the support you need to get the most out of your CAD/CAM investment.

Give the world’s #1 CAM software a test drive. Download Mastercam Demo/Home Learning Edition at no cost. Use it to learn Mastercam and get familiar with the latest advances in CAD/CAM – every step of the way up to actually machining a part!

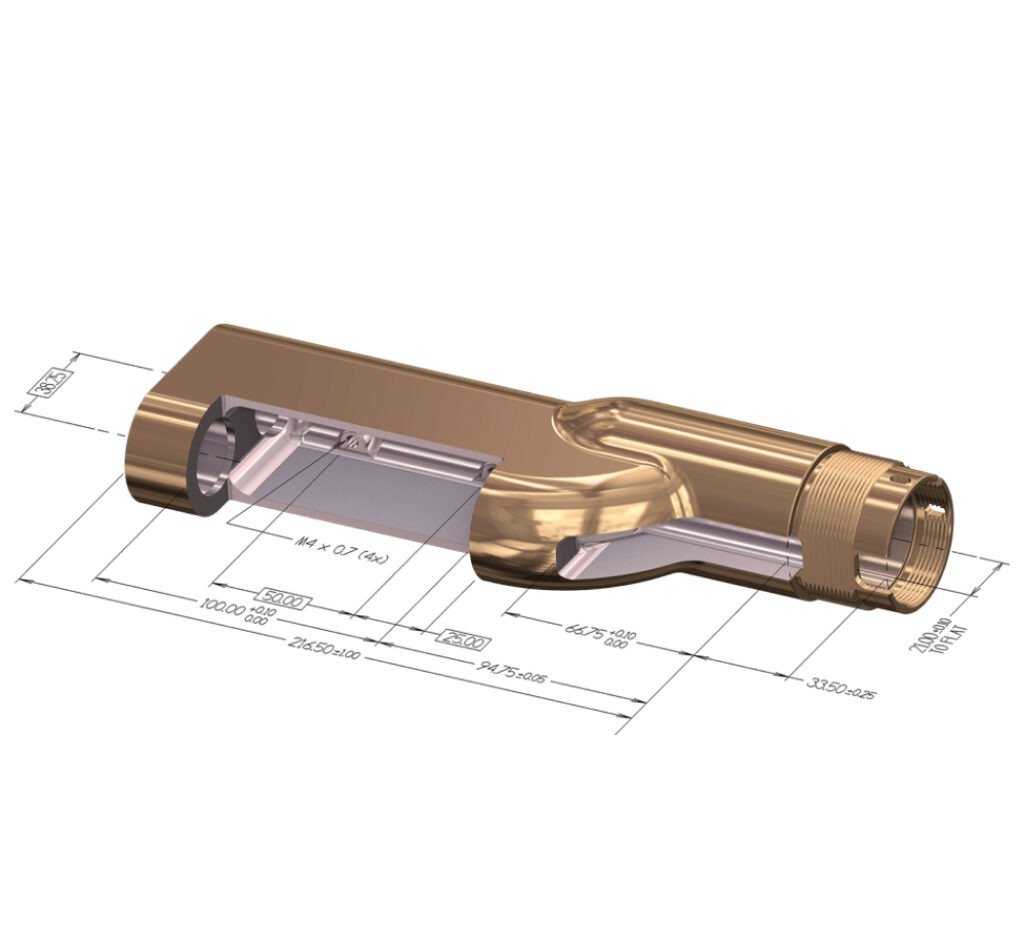

Lathe

Our lathe cam programming software gives you a set of tools to turn your parts exactly as you need them. Mastercam Lathe provides easy roughing, grooving, threading, parting, boring, drilling, and finishing routines for increased productivity.

Product Overview

Mastercam Lathe also delivers a set of C-axis programming tools, with greatly expanded options when combined with Mastercam Mill, such as face contour and drilling and cross contour and drilling.

- Integrated CAD for CAM provides a powerful set of tools for creating and manipulating wireframe, surfaces, STL, and solids data including MBD information (with select translators).

- Advanced toolpath strategies turn parts with greater efficiency and precision.

More people use Mastercam than any other CAM software. From CAD inception to the creation of a final machined part, Mastercam is designed as a comprehensive solution for manufacturing efficiency.

- Full 3D CAD modeling.

- Context-sensitive help available from all dialog boxes.

- Powerful Multiaxis tool motion.

- Mill-Turn for Lathe.

- Quick toolpath functions let you program basic parts with just a few clicks.

- Easy roughing, finishing, threading, grooving, boring, drilling, and cut off.

- Intelligent, stock-aware toolpaths.

- Robust 3D solids and surface machining.

- Complete tool library and custom tool support.

Features

Quickly translate geometry and create a part transfer operation from the main spindle to sub spindle and/or a bar pull operation prior to a cutoff toolpath.

Includes roughing to a boundary for castings.

Machine any job with the combined power of C- and Y-axis machining.

Automatically stop machining to check the insert during your roughing, finishing, and grooving operations

Open virtually any CAD file in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Take advantage of innovative profile tools and processes aimed at greater efficiency and higher machining productivity.

Available in Mastercam Lathe, Mill, and Mill-Turn.

Get the confidence to run the most complex toolpaths on your machine and ensure your parts are done right the first time.

Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

Design

Mastercam Design is a computer-aided design solution that simplifies the creation of even the most complex parts with a robust suite of CAD tools. Design is included with Mastercam’s suite of CAM solutions. It is also available as a standalone product.

Product Overview

From fixing flaws in an imported model, to creating fixtures for work holding on a machine-and so much more, this powerful CAD engine includes modeling and prep tools for CAM programmers to get parts on and off machines quickly.

- Comprehensive CAD platform.

- Direct modeling, file import functionality, and model prep.

- CAD for CAM supports production efficiency.

A notable advantage of our integrated CAD for CAM is the ability to import files from virtually any computer-aided design source. Mastercam includes a large selection of CAD model importers, so no matter where a model was created, you can import and modify as needed for your machining purposes.

- Mastercam can read CAD files from ASCII, CADL, DWG, DXF, EPS, IGES, Inventor (IPT, IDW, IAM), KeyCreator Files (CKD), Parasolids, Rhino 3DM, SOLIDWORKS (SLDPRT, SLDASM, SLDDRW), SAT (ACIS solids), Solid Edge (PAR & PSM), SpaceClaim Files (SCDOC), STEP, STL, and VDA.

- Specialty data translators are available to read CAD files from UG/NX, CoroPlus®, Creo, and CATIA™.

- Full 3D CAD modeling.

- Import, create, and manipulate wireframe, surfaces, STL, and solids data.

- Mastercam Art makes it possible to work with files including JPG, TIFF, and raster-based images—and create a 3D relief based on user preference.

Features

A comprehensive suite of tools for the creation/import and editing of models to modify and prepare for machining.

This suite of tools found on the Model Prep ribbon allows you to modify solids that have no history to edit. You can select faces of a solid body to change the length, you can modify the radius of fillets or remove them all together. You can select bosses or cavities and move them, copy them, or eliminate them entirely.

Dimensions, labels, and notes are part of our drafting functionality to communicate important design information to the shop floor.

Includes everything you need for the creation and editing of lines, arcs, splines, and points. Beyond 2D sketch creation, 3D capabilities offer unlimited flexibility to create the geometry you need with ease.

Surface modeling is an excellent way to create, edit, and display shapes from simple surfaces of revolution to complex organic shapes that cannot easily be done with wireframe. Mastercam gives you a powerful set of surface design tools for straightforward control over every detail of your work.

Allows you to construct models from the simplest wireframe sketches and to continue to edit the model to meet your desired result. These functions create a sequential history of individual operations that can easily be edited as required and update downstream operations automatically. These functions offer a great amount of flexibility for future change.

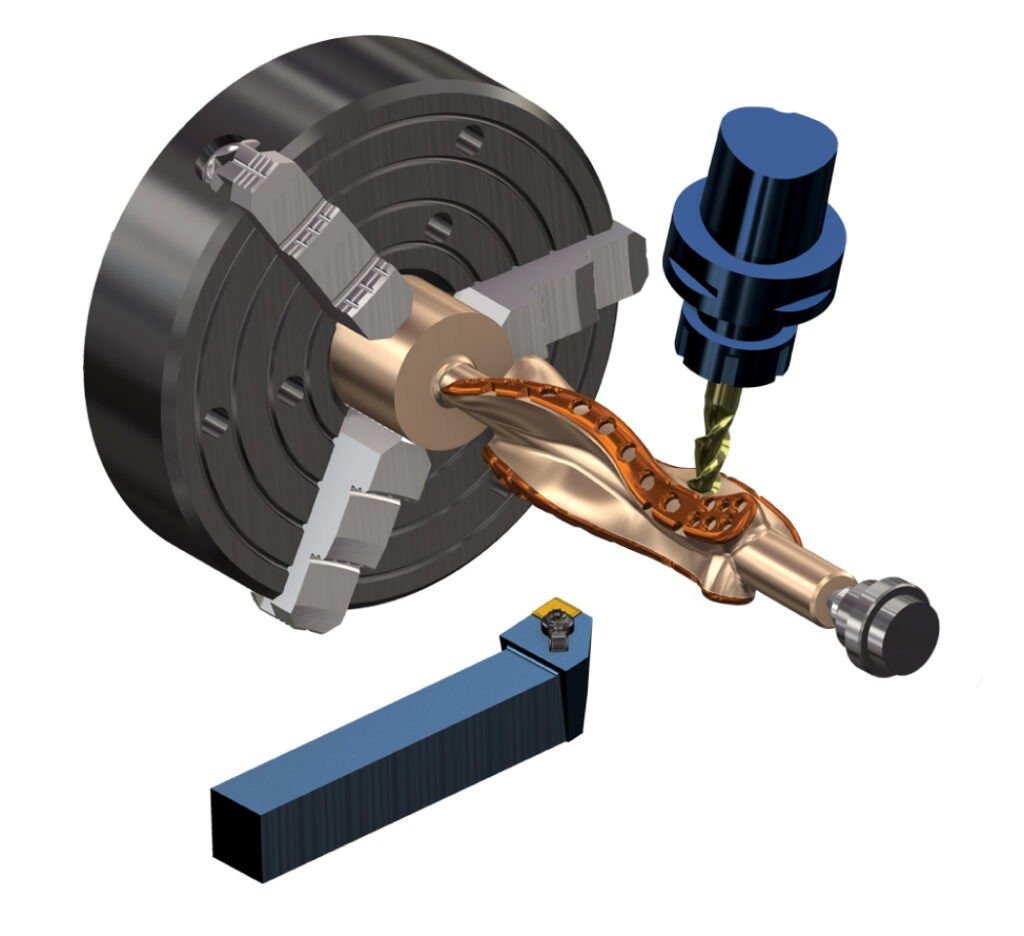

Mill-Turn

Mastercam Mill-Turn programming streamlines high-power multistream machine centers for increased performance and safety. These multitasking CNC machines reduce multiple setups, manual part handling, redundant fixturing, and idle time for improved productivity in manufacturing.

Product Overview

Using Mastercam’s proven milling and lathe toolpaths, this software simplifies the programming process for mill-turn machines with job setups keyed to the exact machine in your shop.

- Optimization, synchronization, and visualization in a single platform.

- Automation to easily manage complex operations between multiple machine data streams.

- Efficient milling, turning, and drilling operations with fewer setups at high speed.

- Program simple lathes in addition to complex machines.

This lathe mill combination programming software provides a set of routines to program complex parts and test your cutting strategies in a single environment—before your stock is on your multitasking machine. You can use Mill-Turn to machine parts without fear of costly collisions or machine damage.

- Automated job setup

- Intelligent, stock-aware toolpaths

- Powerful Gantt- or Tree-style synchronization

- Intuitive part handling tools specific to your machine

- Full machine simulation with accurate visual feedback

- Powerful multiaxis cutting

Mastercam Mill-Turn provides a custom machining environment in which the machine configuration and limits are captured and displayed graphically to ensure safety and quality.

Features

A full design package based on a machinist’s needs, including wireframe, surfaces, and solids design; open most CAD files in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Mastercam’s proven toolpaths, intuitive part handling, automated job setup, 3D tooling support, customized milling tools optimized for mill-turn machining, deburring, support for 2- through 5-axis toolpaths, multiturret, multispindle, and more—all managed in a single machine environment.

Detect collisions between your stock, tool, and machine components before sending code to your machine tool. Machine Simulation is a safe way to prove out 3-axis, 4-axis, or 5-axis toolpaths to make clean, efficient, and accurate programs.

Optimize machine movement and synchronization between turretsand spindles with this state-of-the art interface to generate accurate and efficient code.

Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

Mastercam Mill-Turn allows you to have a complete post, additional tools made for those machines like pinch and balanced turning, and ease of use for twin spindle, twin turret, and B-axis head machines.

As a result of being part of the Sandvik network, Mastercam Mill-Turn users get the benefits of industry-leading technology like PrimeTurning™ automated toolpath strategies and CoroTurn® tools.

Swiss

You no longer need a separate software package for CNC Swiss machines — something programmers and machinists appreciate. Give your shop the convenience and precision of Mastercam Swiss Machining Solutions for gang-style machines and select gang-turret and B-axis machines.

Product Overview

Our Swiss Solutions combine Mastercam Mill and Mastercam Lathe, with an optimized post processor to give you a reliable set of tools to program parts for your Swiss machines—exactly how you need them.

- This bundle of technology delivers precision G-code and the flexibility to standardize your shop with a single software package to program a wide variety of Swiss machines.

- Provides enhanced POCO (Pick-Off Cut-Off) strategy.

- Includes multi-stream NC program viewing.

- Customized Swiss posting options allow for more accurate G-code programming.

- Integrated CAD for CAM provides a powerful set of tools for creating and manipulating wireframe, surfaces, STL, and solids data.

Programming in the Lathe product provides easy roughing, grooving, threading, parting, drilling, boring, and tapping. You can also perform milling operations with Mastercam’s proven toolpaths such as Contour, Drill, Dynamic Motion, OptiRough, Pocket, and Project for increased productivity. Mastercam Lathe also delivers a set of C-axis programming, with greatly expanded options when combined with Mastercam Mill, such as face contour and drilling, and cross contour and drilling.

More people use Mastercam than any other CAM software. From CAD inception to the creation of a final machined part, Mastercam is designed as a comprehensive solution for manufacturing efficiency.

- Easily add machine options and custom code to post output

- Use existing Mastercam Mill or Mastercam Lathe knowledge to quickly produce Swiss programs

- Maintain program uniformity throughout your shop

- Intelligent, stock-aware toolpaths

- Robust 3D solids and surface machining

- Complete tool library and custom tool support

- Flexibility to swap programmed part to different machine makes and models

Features

You are provided with customized parameters directly within Mastercam for lathe stock advance, specific machine setup parameters, expandable custom machine options, and user-specified options.

Machine any job with the combined power of C- and Y-axis machining.

Mastercam Swiss Solutions deliver a simple and effective way to get clean, proven G-code.

Open any CAD file in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Our Mastercam Representatives bring years of practical experience specific to various regions, manufacturing goals, and language requirements worldwide, to ensure that as a Mastercam user, you always have the support you need to get the most out of your CAD/CAM investment.

Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

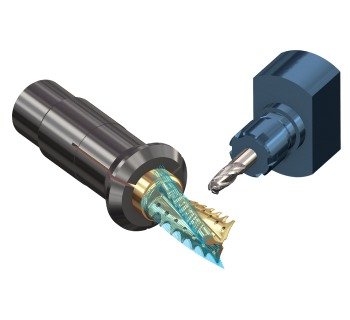

Wire

Fast, easy, and productive—the way programming should be. Mastercam Wire is a solution for programming CNC Wire EDM machines.

Product Overview

Mastercam’s suite of 2-axis and 4-axis wirepaths lets you choose the best method for the results you need, with control over the wire motion, angle, entries and exits, and much more. And you get that control in a clear, easy to understand way.

- Full-featured design capabilities support any combination of modeling, from wireframe to surfaces to solid models.

- Automatic lead-in and lead-out strategies, fast, flexible tab creation, and no core cutting make Mastercam Wire a powerful tool for quickly programming parts.

- Intelligent NC programming lets you build a library of machining strategies that automatically adapt to new models.

- Mastercam Wire complements the functionality of other products such as Mastercam Mill and Lathe.

The Mastercam platform is the most widely used and well known in the world of CAM. Shops using other Mastercam products that want to program wire EDM machines choose Mastercam Wire for a rapid return on investment.

- Reduced time to find experienced individuals to use the software.

- Familiar, user-friendly interface improves programming efficiency.

- Efficient wire toolpaths deliver precision wire machining.

- Power libraries for almost any wire machine.

Features

You can import geometry from virtually any source and create new geometry, giving you a high degree of flexibility to use your data for reliable programming.

Gives you the power to capture your work and build on your experience; once you program a part—any part—you can modify any element of a job and get updated wirepaths immediately, without starting over.

Easily ensure the toolpath motion delivers exactly what you intended with Mastercam’s wirepath verification tools.

With fast, easy, and complete control over tab creation you can quickly add multiple tabs to any piece of geometry.

Our Mastercam Representatives bring years of practical experience specific to various regions, manufacturing goals, and language requirements worldwide, to ensure that as a Mastercam user, you always have the support you need to get the most out of your CAD/CAM investment.

Geometry and toolpath nesting provide an extremely fast way to program several parts while utilizing stock efficiently to reduce scrap.

Router

When you invest in a CNC router machine, you want the right router software driving it to maximize productivity and avoid downtime due to costly errors. Mastercam Router delivers the right tool exactly when you need it.

Product Overview

Anyone with a CNC router, from the home hobbyist to professional manufacturers, can appreciate the ease, speed, and reliability of Mastercam Router software. The software delivers industry-proven CNC programming for safe and efficient router machining of everything from wood to composite materials.

- From CAD inception to part completion, Mastercam CNC Router software is designed as a comprehensive solution for manufacturing productivity.

- Mastercam CNC Router software supports features that are unique to CNC routers, including toolpath and geometry nesting, block drill support, aggregate head support, saw cutting support, and full 2- through 5-axis cutting.

Many CAM packages for CNC routers are limited in scope, but with Mastercam, you have the flexibility to do more. From simple 2D programming to complex 5-axis machining, the world’s leading CAM Software helps get the best performance out of CNC routers.

- Full 3D CAD modeling.

- Versatility to program simple contours and nest them or set up Automatic Toolpathing (ATP).

- Powerful Multiaxis tool motion.

- Complete tool library and custom tool support.

- Specialized options like Art and 5-Axis Curve Machining and Drilling.

- Toolpath creation, verification, and simulation for any CNC router.

- Feature-rich product allows shops to diversify as needed to remain competitive.

Features

Detect collisions between your stock, tool, and machine components before sending code to your machine tool. Machine Simulation is a safe way to prove out 3-axis, 4-axis, or 5-axis Router toolpaths to make clean, efficient, and accurate programs.

Standard nesting delivers a fast, efficient, and easily identifiable way of nesting. Advanced nesting gives you a variety of additional tools, including TrueShape nesting and nesting in scrap material.

You can create signs, artistic carvings, molds, and more.

Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

Links you to a variety of top design software to read in entire projects and have them program automatically using presets that you choose.

Automatically take apart your assemblies and move the components to different levels based on part thickness.

Evaluates a part’s features and automatically designs an effective machining strategy.

From direct editing of your solid models to advanced free form surfacing capabilities in Model Prep, Mastercam takes you from an idea to a completed part faster and more efficiently.

Total Materia

Product Overview

Total Metals

Total Metals is by far the world’s largest database for metallic material properties and sits at the core of the Total Materia product offering serving as the gateway for an unparalleled collection of datasets and modules which serve the global engineering community.

Focused on providing standard metal properties data, Total Metals provides you with a staggering 15,000,000 property records for over 350,000 materials from 74 countries/standards.

What’s Inside

- Properties for 450,000+ Materials

- 3,000+ Sources for Advanced Data

- Metals, Polymers, Ceramics, Composites

- 150,000+ Stress-Strain Curves

- 74 Standard Development Organizations

- 35,000+ Materials with Cyclic Properties

- International Cross-Reference Tables

- Property Estimation and Interpolation

- Chemical Composition

- Data Export to CAE Software

- Mechanical and Physical Properties

- Identification of Unknown Materials

- Multiple Material Comparison Options

- Standard and Material Update Tracking

Product Editions

Total Materia can be accessed through a range of product format options, including a single user web edition, and flexible web subscriptions for multiuser set ups for companies small and large, and corporate solutions for international businesses.

With only an internet connection and browser required for web editions, Total Materia offers a hassle free, turn-key solution for access to world’s most comprehensive materials database.

Product Packages

Total Materia has a package and licensing option to suit your needs. From our smallest single user packages to our global corporate licenses, Total Materia offers exceptional added value to your engineering tasks.

Download more details and information about Total Materia solutions and modules

Flagship database offering the ultimate in standard materials properties data including composition, mechanical and physical properties, heat treatment diagrams, cross-reference tables and much much more for over 350,000 alloys!

New non-metallic material database offering access to material properties for thousands of plastics, ceramics and composites including mechanical, physical, thermal and electrical properties.

Provides an unparalleled material properties resource for advanced CAE/FEA structural and thermal calculations and analysis and includes thousands of stress strain curves, cyclic properties and formability curves and more.

Supplementary module providing data subsets covering joints information, lubricants and coolants, material dimensions, tribology, and coatings for thousands of metallic and non-metallic materials.

Additional data module providing corrosion data, irradiation, weathering and aging information for thousands of metallic and non-metallic materials.

The Compliance module provides a single source of information about global regulations for materials and substances.

Browse, search and quickly find material suppliers from all over the world in combination with the Total Metals Database which provides accurate connection between materials, their properties and potential local or global suppliers.

Identify unknown materials from chemical composition which has been generated by spectrometer. Find matches from one of the 350,000+ metals and then view material property data and cross-references at the click of a button.

Export material property data into CAE solver formats in 3 simple steps including formats such as ANSYS, HyperWorks, Abaqus, Siemens NX and many more.

Make sure that the data being used is the most up to date and therefore most reliable information available. See exactly what has changed within the database and when from standard version updates to property data changes.

Material Console provides multiple functionalities to support more efficient,

accurate and personalized material selection decisions.

Total Materia Integrator is a new software for creating a private company database of material information, whether it be internal standards and regulations, test data or external data sources.

To help find additional options for material selection consideration,

Equivalents Finder allows you to create a list of similar materials based

on the properties most important to you.

Material Discovery takes material selection to the next level by providing

visualization of material groups by analyzing more than 500,000 real materials!

With analytics you can visually compare a list of predefined materials

for the most important property parameters according to your application.

Make critical material selection decisions

Compare for properties of your choice

Quick view via plotted points

Consider ranges with rectangle view

Click in to see data at the condition level

Product compliance and sustainability.

Understand how your design activities and products impact the environment.

Support responsible material selections from the start.

Applied machine learning

for material property predictions

M I S S I N G D ATA - F I L L I N G T H E G A P S

Fill gaps in available data to drive more

accurate calculations

Selection opportunities by predicting

properties for new materials

Save money by reducing material

testing costs

Total Metals

Total Metals

Total Metals is by far the world’s largest database for metallic material properties and sits at the core of the Total Materia product offering serving as the gateway for an unparalleled collection of datasets and modules which serve the global engineering community.

Focused on providing standard metal properties data, Total Metals provides you with a staggering 15,000,000 property records for over 350,000 materials from 74 countries/standards.

The Challenges

- Finding equivalents to foreign materials and comparing alternatives side by side

- Searching for materials worldwide by specific chemical composition or mechanical properties

- Deciphering material specifications and finding the correct grade for a specific application

- Finding precise traceable and reliable mechanical, physical and other property data for various conditions and temperatures

- Following the ever increasing pace of changes to national and international standards

The Solution: Total Materia - Total Metals

THE LARGEST, TOP-QUALITY DATABASE

From chemical compositions, cross-reference tables, mechanical and physical properties at room, elevated and subzero temperatures, to additional information such as heat treatment diagrams, metallography and machinability, Total Metals gives you the highest quality and reliability of the only certified database of its kind in the industry.

THE FASTEST AND MOST POWERFUL CROSS-REFERENCING

The most comprehensive cross-reference tables with more than 15,000,000 records for equivalent materials worldwide are systemized using a proprietary classification of similarity. In addition, patented SmartCross2 algorithm enables identification of unknown equivalents using similarity of composition, mechanical properties or their combination.

UNPARALLELED DEVELOPMENT & CUSTOMER SUPPORT

Total Metals materials and property information are updated every month, keeping you up-to-date with the newest standards developments, as well as upgraded with new datasets, new unique algorithms and new software features. All aspects of Total Materia are fully supported by a dedicated team of specialists with over 300 years of combined industrial experience that provides technical consulting support FREE of charge for all subscribers!

PolyPLUS

PolyPLUS

PolyPLUS is the non-metallic material properties dataset for thousands of plastics, ceramics and composites covering both proprietary and standard materials and including advanced property datasets.

Integrated with the Total Metals database which contains over 350,000 metallic alloys, PolyPLUS allows Total Materia to be used as a truly one stop solution for your material needs.

The Challenges

- Finding precise traceable standard and proprietary material property data for polymers, composites and ceramics

- Simultaneous comparison of different kinds of metallic and non-metallic materials and finding the best alternatives

- Sourcing rare advanced properties information for FEA/CAE calculations including stress-strain and fatigue data

- Inefficiency of working from multiple resources covering metals and non-metals and across multiple business departments and disciplines

The Benefits

One stop resource for all material properties data needs; new opportunities in design by comparing the performance of completely diversified materials

The Solution: Total Materia - PolyPLUS

The PolyPLUS module from Total Materia offers non-metallic material properties data for thousands of plastic, ceramic and composite materials covering a wide range of standard and advanced property information.

ADVANCED PROPERTY DATA FOR NON-METALS

As well as housing a unique collection of advanced property data for metallic materials, Extended Range also offers a comprehensive set of stress strain curves and fatigue data for non-metals.

UNPARALLELED DEVELOPMENTS AND UPGRADES

Through our dedicated PolyPLUS team, new data and functionality upgrades are added on a monthly basis meaning that our growing library of non-metals is fast becoming an indispensable resource for the engineering community.

ULTIMATE ONE STOP RESOURCE FOR ALL MATERIAL PROPERTY NEEDS

In combination with the world’s most comprehensive metals properties database, PolyPLUS provides the all the benefits of the Total Metals database, but for non-metals including property information for thousands of plastics, ceramics and composite materials and all available at the click of a button!

DataPLUS

DataPLUS is a supplementary module providing data subsets covering joints information, lubricants and coolants, material dimensions, tribology, and coatings for thousands of metallic and non-metallic materials.

In synergy with the primary materials databases, Total Metals and PolyPLUS, DataPLUS supports and supplements key industrial application decisions by helping make accurate and considered choices relating to material selection and usage.

The Benefits

Drives more accurate material selection; Helps justify material placement according to application; Common tool for both engineering and purchasing helping to get it right first time

The Challenges

- Material and consumables selection for successful welding operations

- Finding coatings and their properties related to materials in one unified platform

- Communicating between engineering and purchasing avoiding potential errors

The Solution: Total Materia - DataPLUS

DataPLUS covers a wide range of information within its five data sub-sets acting as a critical additional resource for the process of material selection. Completely integrated, DataPLUS connects seamlessly to other key information such as chemical composition, tables of equivalent materials, mechanical and physical properties, which means viewing the bigger picture is effortless.

WELDING INFORMATION FOR GLOBAL MATERIALS AND CONSUMABLES

Find critical welding information such as mechanical properties at joint, information for thousands of material combinations, base material property data, consumable characteristics and references to related welding methodologies.

LUBRICANT AND COOLANT MATERIALS AND TRIBOLOGICAL DATA

Make key decisions about suitable lubricants and coolants to reduce cost by ensuring optimized part life. In combination with tribological data for thousands of materials, a complete picture of surface interaction can be discovered.

Find tribological data to understand the friction and subsequent wear potential for thousands of international materials and to help avoid unnecessary power loss and part degradation through the correct lubricant and coolant selection.

FIND DIMENSION AND TOLERANCE INFORMATION IN SECONDS

A must have to bridge the gap between engineering and purchasing, the dimensions and tolerances dataset allows you to find information relating to specific material measurements, their permissible variations along with useful information about packaging formats.

SEARCH FOR COATINGS INFORMATION TO UNDERSTAND PERFORMANCE

Hundreds of coating designations available with multiple properties and test data to help drive accurate decisions relating to coating selection and performance. Using the simple search interface, find properties such as coefficient of friction, maximum working temperature, micro hardness and much more.

Extended Range

Total Materia’s Extended Range dataset provides an unparalleled material properties resource for advanced structural and thermal calculations and analysis including: stress-strain curves, formability diagrams, fatigue data and more.

The Challenges

- Finding material data essential for advanced engineering calculations and computer aided engineering (CAE) and finite element analysis (FEA) simulations

- Obtaining stress-strain curves at various temperatures and at different strain rates

- Comparing fatigue properties of different origins for example American, European and Asian materials

Avoiding costly and potentially dangerous errors; opening new opportunities for more optimized and cost-effective design; enhancing accuracy and efficiency throughout the entire process chain.

The Solution: Total Materia - Extended Range

Extended Range offers a unique collection of advanced property data for use in critical design activities and brings effortless efficiency to the extremely time consuming task of finding reliable material property information, specifically for advanced linear and non-linear calculations. To achieve this, experimental data from over 3,000 references and documents, dating from 90 years ago to the most recent sources, have been processed and included using a proprietary data acquisition methodology.

THOUSANDS OF STRESS-STRAIN CURVES

Unique collection of more than 150,000 stress-strain curves for calculations in the plastic range covers more than 20,000 materials, with various heat treatments, working temperatures and strain rates, from quasistatic to over 1,000 1/s. Both true and engineering stress curves are given, with a possibility to interpolate curves for user-defined temperatures and strain rates.

LARGEST COLLECTION OF CYCLIC PROPERTIES

The largest database of strain-life and stress-life parameters for more than 35,000 materials, e-N and S-N diagrams, for various heat treatments and loading conditions. Monotonic properties are included for reference along with statistical fatigue parameters where applicable.

PROPRIETARY METHODOLOGY FOR PROPERTIES ESTIMATION

Based on Total Materia cross-reference tables and properties of equivalent materials, Extended Range provides estimates for stress-strain curves for additional 90,000 materials and cyclic properties for another 80,000. Although estimates cannot completely replace experimental data, they provide a valuable starting point for further research and calculations.

MORE ADVANCED PROPERTIES FOR DESIGN AND SIMULATION

Forming limit and high-strain curves at a range of temperatures, for simulating forging, drawing and other forming operations. Fracture mechanics K1C, KC, crack growth and Paris law parameters are presented, with the corresponding graph of crack growth. Creep data including yield stress and creep rupture strength at different temperatures with the calculation of Larsen-Miller parameter and remaining life of the component.

Total Materia Enviro

Enviro is an additional data module providing corrosion data, irradiation, weathering and aging information for thousands of metallic and non-metallic materials.

In synergy with the primary material databases, Total Metals and PolyPLUS, Enviro aids material application decisions by providing a comprehensive understanding of material behavior under the influence of a range of diversified impactful effects.

The Benefits

Reducing risks and increasing safety in exploitation; Higher prevention rate of material failure during product life; More knowledge for key design and material selection decisions

The Challenges

- Risks and potential catastrophic failures in exploitation

- Predicting product life under a range of influences deriving from external effects

- Ever increasing quality and performance challenges during product useful life

- Supporting innovation by aiding complete and thorough material selection decisions

The Solution: Total Materia - Enviro

Enviro focusses on four complimentary datasets which provide even more breadth and depth to the information provided within the fully integrated platform of Total Materia. Covering corrosion, weatherability, irradiation and different types of aging effects, Enviro provides a key source of information to design, manufacture and sell products of greater quality and longevity in to the market place.

CORROSION DATA FOR THOUSANDS OF MATERIALS

Find information about material corrosion rates and corrosion resistance in acid and aqueous environments and at a range of temperature conditions. Find direct information for a specific material using an intuitive filter to select the most suitable condition for you including media, temperature, exposure time, and corrosion type.

WEATHERABILITY AND ENVIRONMENTAL EXPOSURE INFORMATION

Typically associated with polymers, weatherability information provides important exposure information for solar, moisture, heat, pollutants, saline water and even microbial attack for thousands of materials. Helps tackle key material integrity issues by avoiding chemical process changes, weakening of material properties, and aesthetic issues such as coloration.

AGING EFFECTS AND RELATED PROPERTIES DATA

Delivering a range of aging (time) information in a combination of one or more additional factors, which cause a general degradation of material integrity and can therefore have a serious impact on the long-term application of the materials. Covered additional factors in combination with time include thermal, chemical, and weathering effects.

IRRADIATION INFLUENCES ON MATERIAL BEHAVIOR

A key dataset for the nuclear industry, irradiation data provides a clear relationship between exposure time, radiation dosage and the subsequent effects on the material properties. Irradiation of materials can cause potentially catastrophic failures relating to swelling, creep and general embrittlement of the exposed materials.

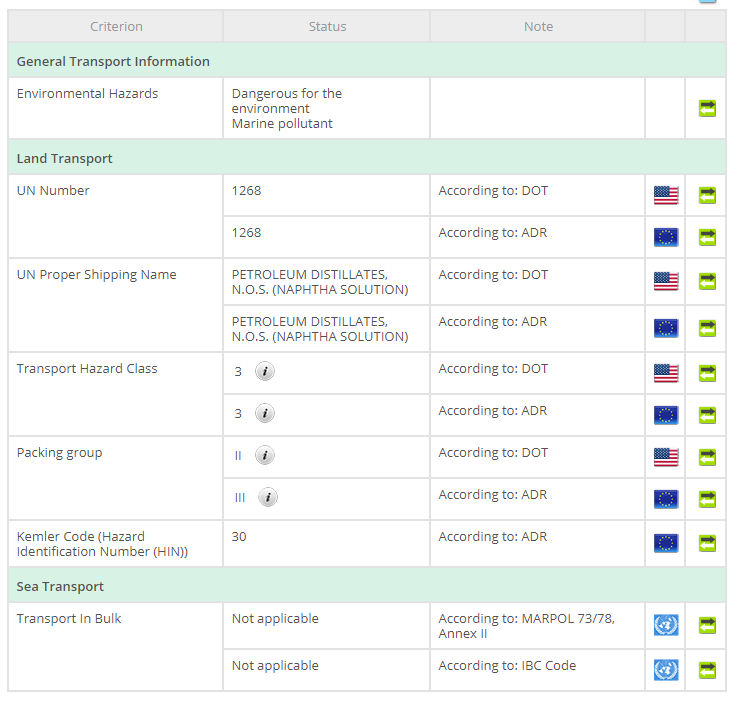

Total Materia Compliance

Compliance

The Compliance module provides a single source of information about global regulations for materials and substances.

Comprising inventory lists, hazard identification, transport information and much more for thousands of materials, Compliance includes international regulations, such as REACH and RoHS, national, from the US to Japan, China and Russia, as well as specialized regulations such as food industry, water and sanitation, all integrated and searchable with material properties information.

The Benefits

Safeguarding the business by reducing the risk of noncompliance; Add new dimension to the processes of material selection; Huge time savings in compliance analysis and due diligence

The Challenges

- Costly penalties and exclusion from the market resulting from noncompliance

- Deciphering complex and diversified rules in different countries and even regions

- Staying up-to-date with ever changing rules and regulations

- Huge time and effort needed to gather information and apply it to the product line

The Solution: Total Materia - Compliance

The Compliance module offers a global view of up-to-date regulations for both materials and substances, allowing businesses to keep pace with the ever increasing pressure for companies to meet their legal obligations related to their products, components and the materials they use. Compliance helps in a variety of complex tasks such as the design and launch of a new product, converting an existing portfolio to meet regulatory guidelines, approving vendors, controlling materials and more.

QUICK ASSESSMEMT OF MATERIAL SUITABILITY FOR INTERNATIONAL SUPPLY CHAIN

Owing to its coverage of international and national regulations, Compliance provides a possibility to quickly assess a globally created product, that can for example be designed in the US, with componentry from Japan, manufactured in China using local raw materials and substances, which will be eventually exported to the EU.

COMPANY-WIDE CENTRALIZED, UP-TO-DATE COMPLIANCE INFORMATION RESOURCE

Whether the objective is to assess new materials in conceptual design, to revise bills of materials for existing products, to test a new component in the laboratory, to compile due diligence documents, or to assess a new supplier, the Compliance module provides quick and simple access to centralized, unified and up-to-date information, thus eliminating errors throughout the workflow.

NEW LEVEL OF INTEGRABILITY

In combination with a vast resource of basic and advanced material properties, compliance information, compliance of substances and all related international regulations can be readily exported to the company’s IT systems such as Product Lifecycle Management and Enterprise Resource Planning, which allows huge savings and enhances information flow.

Total Materia Suppliers

Suppliers (Beta)

The Suppliers module in synergy with the Total Metals module gives you precise connections between material specifications and suppliers from all over the world.

Allowing a direct link between materials of interest and finding suppliers across the globe, Suppliers allows for maximized communication and a critical starting point for the purchasing process.

The Benefits

Opens new opportunities for cost saving in material sourcing; brings engineering and procurement together; linking materials with suppliers helping avoiding costly errors in the decision making process

The Challenges

- Checking for suitable suppliers quickly according to a range of selected materials

- Coping with price volatility and meeting tight deadlines for material delivery by searching for alternatives in lower cost countries

- Finding material suppliers in other countries to help coordinate global purchasing activities

- Improving communication between engineering, purchasing and manufacturing

The Solution: Total Materia - Suppliers

Maximizing efficiency between engineering and purchasing cross functional activities, Suppliers gives excellent time saving opportunities through three main benefits.

IDENTIFICATION OF SUPPLIERS AT THE CLICK OF A BUTTON

Browse, search and quickly find material suppliers from all over the world. Suppliers and their materials are precisely related with designations and standards, in combination with Total Metals and PolyPLUS which holds over 450,000 materials, with an interface as simple as point-and-click

ULTIMATE SEARCH FLEXIBILITY FOR ALTERNATIVES

Look for alternative materials by using worldwide unique, patented technology for finding equivalents by chemical composition and by mechanical properties and any combination thereof. You can intuitively set the importance level of composition versus mechanical properties and the alternatives are displayed according to their similarity, with a hotlink to the Total Materia Database for detailed properties comparison.

LARGEST NUMBER OF COUNTRIES & LANGUAGES FOR CROSS FUNCTIONAL, INTERNATIONAL COMMUNICATION

Provides a vital tool in communication between departments from engineering to purchasing and with the database covering materials from 74 countries, suppliers from across the world, and a platform that is available in 26 languages, Total Materia provides the complete solution.

Total Materia SmartComp

SmartComp

SmartComp, the add on module from Total Materia allows intelligent metal identification by chemical composition obtained from spectrometer or other analytical sources.

Using a patented algorithm, SmartComp can eliminate a huge amount of working time dedicated to research and increases efficiency and functionality of laboratory and inspection business activities by allowing fast, multi-criteria material identification. Owing to integration with Total Materia, material property details and cross referencing to be viewed in seconds, and compared with other alternatives if needed.

The Challenges

- Carrying out complex material identification studies from only chemical composition as a highly experienced expert would do

- Reducing thousands of working hours spent in research to identify materials and this is even sometimes in vain

- Driving down high costs associated with acquiring specifications and standards

- Reducing rework and scrap in the manufacturing environment through effective root cause identification of plant process errors

The Solution: Total Materia - SmartComp

The new generation of spectrometers can generate a material chemical analysis in seconds but how do you then identify the other critical information of the material like grade, origin, and its properties and equivalents. Starting from simply entered chemical analysis as obtained from spectrometer, by using patented algrorithm SmartComp is able to identify matching grades from all over the world, thus dramatically increasing the usability of analysis and overall functionality of laboratory.

EXPERT REASONING THROUGH PATENTED TECHNOLOGY

Design to “think” like an expert, SmartComp carries out what would be extremely time consuming manual research work in a matter of seconds. Using a patented algorithm SmartComp ensures that problematic trap elements, impurities and oligoelements do not bog the identification process down and focuses the search on the most important elements to the user.

POWERED BY THE LARGEST METALS DATABASE

Even the best expert cannot do a lot without a large data library for lookup and comparison. SmartComp is therefore integrated with the Total Materia Database, setting up the possibility to compare the entered chemical analysis with composition data from over 350,000 materials, thus ensuring finding material matches is a hassle free process.

ADVANCED IDENTIFICATION OPTIONS

In addition to Standard identification mode, advanced Expert mode offers a possibility to set the relative importance to each alloying element individually, thus obtaining matching alloys that may be more appropriate for the specific problem. Reference Materials is another module, which facilitates finding materials for calibrating spectrometers.

BEYOND IDENTIFICATION

Identifying matching materials may only be one part of the story. Total Materia allows direct access from the material match list to material properties, thus providing a possibility for a more detailed comparison of candidate materials and their properties, including side-by-side comparison option, and combining comparison of chemical composition and mechanical properties using cross-reference tables and SmartCross2 module.

Total Materia eXporter

eXporter

eXporter is the add on module which primarily helps bridge the gap between data source and computer aided engineering (CAE) software. Whether you want to move data from Total Materia directly to CAE software or simply export in excel or .xml, eXporter provides all the functionality you need. In a form of a simple 3-step wizard, it provides multiple-format data exports in mere seconds.

The Solution: Total Materia - eXporter

Total Materia’s eXporter module works seamlessly with Total Metals and Extended Range data modules to allow properties information to be exported in a format especially developed for the top CAE solvers.

eXporter

The Benefits

Tremendous time savings, whilst relieving you from tedious retyping; increasing accuracy through elimination of data editing errors; streamlining and systemizing data acquisition workflow

The Challenges

- Finding advanced property data for linear and non-linear CAE calculations in a ready to use solver format

- Importing data from source into CAE software without the need for additional data processing, copying, pasting and retyping

- Obtaining reliable inputs for material properties thus avoiding dangerous and costly errors

- Carrying out multiple and repeatable design tasks in the most efficient way possible

Please Note: A maximum of 100 data set exports allowable per concurrent license for the duration of the subscription. All previous exports are available at any time and re-usable an unlimited number of times for the duration of the subscription.

EXPORT FROM THE ULTIMATE RESOURCE

Total Materia offers the world’s largest material properties resource and it is now possible to select data from a collection of over 450,000 materials and 20,000,000 property records, and then export ready for use in the next step of the design process.

COMPREHENSIVE CHOICE OF CAE SOFTWARE FORMATS

eXporter can be used to export critical material data for advanced calculations such as mechanical, physical, stress strain and cyclic data in a number of CAE software compatible formats. From bespoke xml., to simple xls. eXporter makes the transit of data from source to software quick and easy.

SEAMLESS INTEGRATION OF TOTAL MATERIA MODULES

Maximizing the potential of eXporter, the entire Total Metals and Extended Range data sets can be used to find the properties of interest. With full access to the largest international cross-reference tables and comparison functionalities, the full power of Total Materia can be utilized to ensure the selection of data for export is backed up by informed and traceable decisions.

Total Materia Tracker

Tracker

In today’s ever increasing pace of changing international standards, and producer specifications, Tracker is the Total Materia answer to your critical material traceability needs.

Providing a bulletin style monthly notification service, Tracker allows, not only important standard and material updates to be monitored but even gives information on exactly what has changed within the material, whether it be updates to important properties data, addition of completely new datasets, or a simple update to version details.

The Benefits

Confidence that accurate and up-to-date information is used; avoiding unnecessary costs for standards acquisition; driving business excellence through an optimized information usage workflow

The Challenges

- Ensuring the most up to date information available is being used for the job

- Providing reliable, accurate and traceable information to other areas of the business

- Staying up to date with material, standard and specification changes

- Contributing to company best practices relating to information usage, configuration management and overall process quality

The Solution: Total Materia - Tracker

Tracker is the add on module from Total Materia which deals with the important challenge of how to make sure that the data being used is the most up to date and therefore most reliable information available. See exactly what has changed within the database and when from standard version updates to property data changes.

GET MORE BENEFITS FROM UNPRECEDENTED UPDATE POLICY

To cope with ever faster speed of changes on standards and producers' specifications, updates and upgrades to Total Materia are made every single month, making it the most up to date resource available. By providing exact reports of amendments made on the database month by month, Tracker allows informed, reliable and confident decisions to be made for the entire business.

SMART INTUITIVE METHODS FOR UPDATE TRACKING

Tracker combines synthetic reports about materials and standards that have been updated, including version number and withdrawal information, with analytic reports where it is possible to view exactly what has changed at the material level, from basic chemical composition details to new stress strain curves.

FAVORITE MATERIAL SELECTION FOR FOCUSED TRACKING