Advanced Analysis

Moldex3D goes beyond traditional simulation by incorporating advanced analysis capabilities, allowing users to gain deeper insights into the complex behavior of plastic injection molding processes and new applications. By simulating the entire manufacturing process from pre-filling to warpage and plastic material science , Moldex3D enables engineers to optimize their designs, troubleshoot potential issues, and improve overall part quality. With realistic injection function, fundamental material background and advanced simulation, we can help you to solve issue in new field applications!

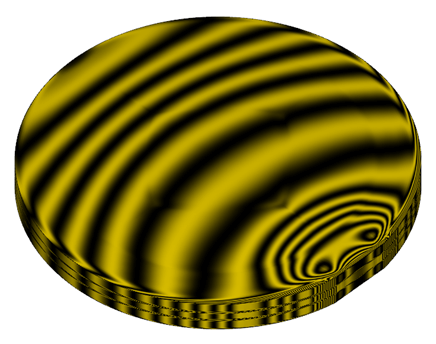

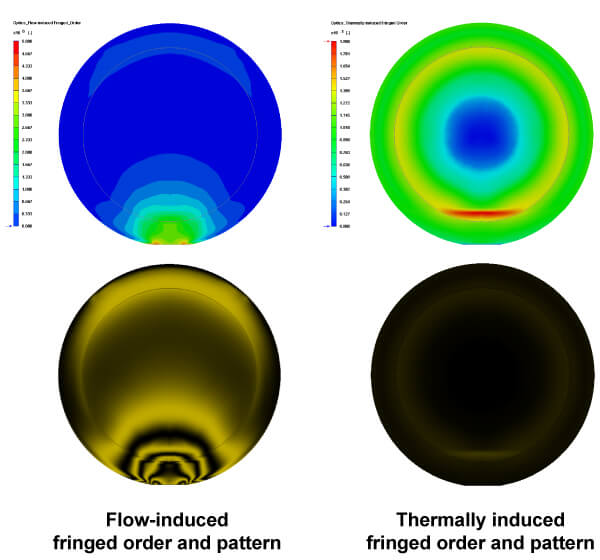

Optics

- Simulate with Moldex3D Optics module to validate flow-induced residual stress effect, and optimize optical properties

- Consider molding conditions, flow-induced residual stress, and viscoelastic effect for warpage and optics characteristics predictions

- Predict optical properties: Birefringence(flow/thermal-induced), retardation, polarization, fringed orders and patterns, refractive index.

- Isochromatic and Isoclinic modes can also be output.

- Integrate with CODE V for further non-uniform refractive index prediction

- For more details please check Optics

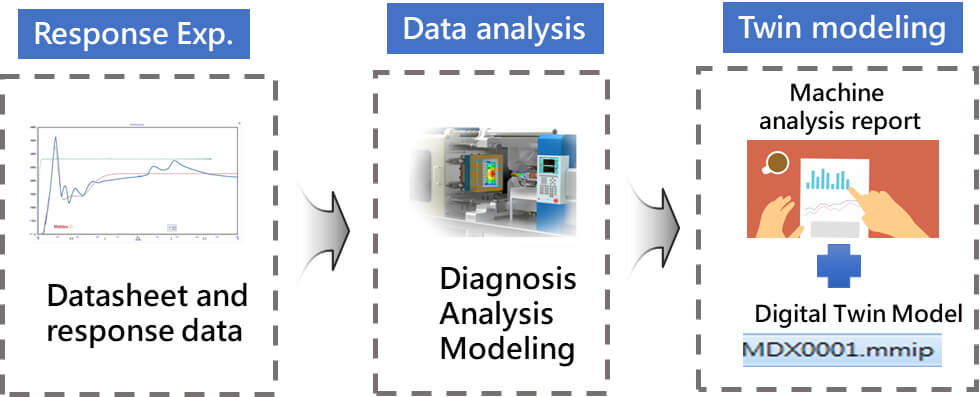

Machine Response

- Machine characteristics can minimize the gap between real machine response (Electric/Hydraulic) and simulation profile setting.

- Machine response data can be collected through series of screw speed and injection pressure experiments, then transfers to Machine response report and data file (.mmip) for more accurate simulation.

- For more detail please check Machine Characterization

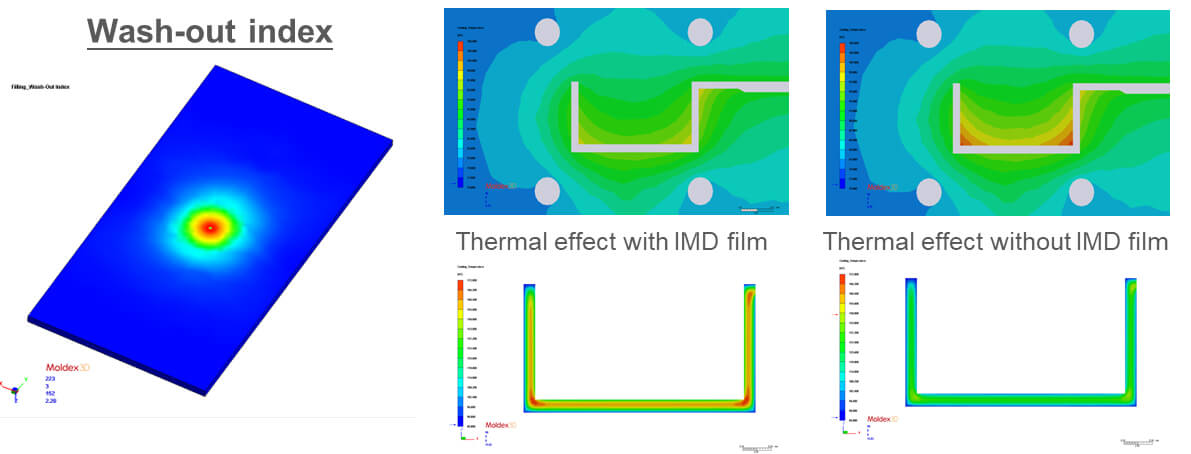

In-Mold Decoration (IMD)

- Provide Wash-Out Index induced by melt filling with easy-to-use IMD BC approach for specifying decoration film

- Predict the thermal effect with film decoration

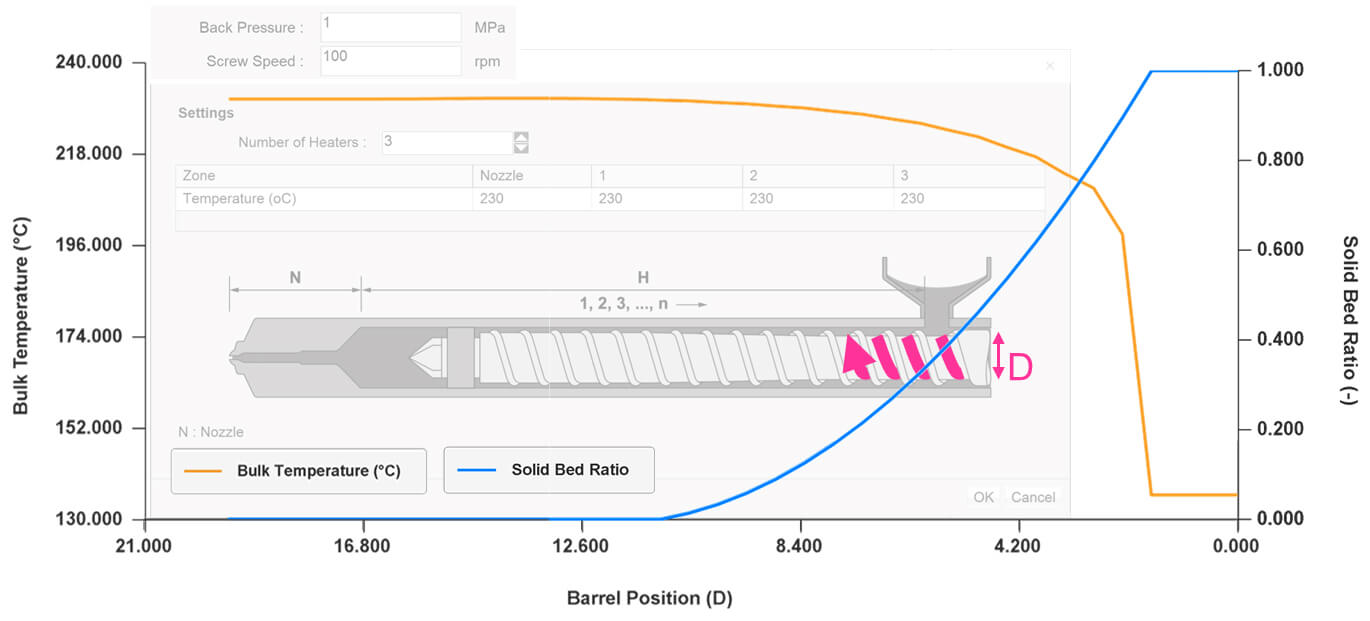

Plastification

- Simulate Plastification Process and the Behaviors inside the Barrel, like Predict Solid bed ratio, Recovery time, Temperature change, etc.

- Estimate plasticizing capacity of the screw.

- Provide more realistic melt inlet condition for better injection simulation.

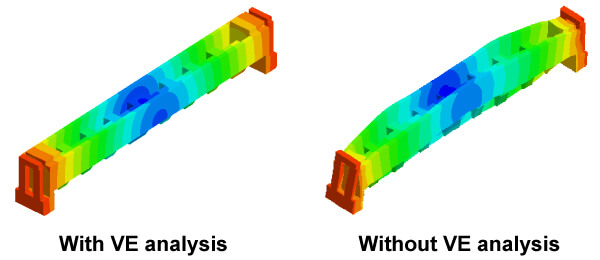

Viscoelasticity (VE)

- Viscoelasticity is another important area within material science and engineering. It pertains to the behavior of materials that exhibit both viscous (liquid-like) and elastic (rubber–like) characteristics and display time-dependent responses to applied stress or strain,

- Viscoelasticity can apply in materials deform, relax, and recover over time, considering factors such as temperature, loading rate, and the duration of applied stress.

- Moldex3D Viscoelasticity analysis can help to display residue stress in Fill/Pack/Cool/Annealing stage and provide more precise result for warpage and optical birefringence.

- For more details please check Viscoelasticity (VE)

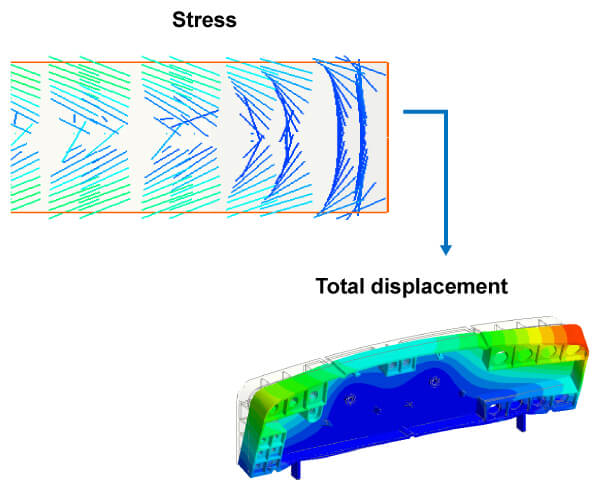

Stress

- Stress analysis is a fundamental aspect of material science and engineering, focusing on the distribution of internal forces within materials and structures.

- Stress analysis plays a crucial role in designing and optimizing structures to ensure their mechanical integrity, product quality and performance,

- Fluid-structure interaction (FSI): analysis the shift or deformation behavior like part inserts, core shift, paddle shift

- Fiber orientation and weld line effect:mechanical property analysis to predict on strength enhance or reduction

- Viscoelastic effect: It can be applied to the residual stress distribution of annealing, product deformation, and optical analysis

- Geometric nonlinear analysis: for the buckle behavior of plastic parts that are prone to warp

- For more information, please refer to the stress webpage