Material Hub Cloud

The Most Comprehensive Material Database for the Plastics Processing Industry

Material Hub Cloud Functions

Material Database Viewer

Check materials conveniently with their data quality index, property curves and processing conditions

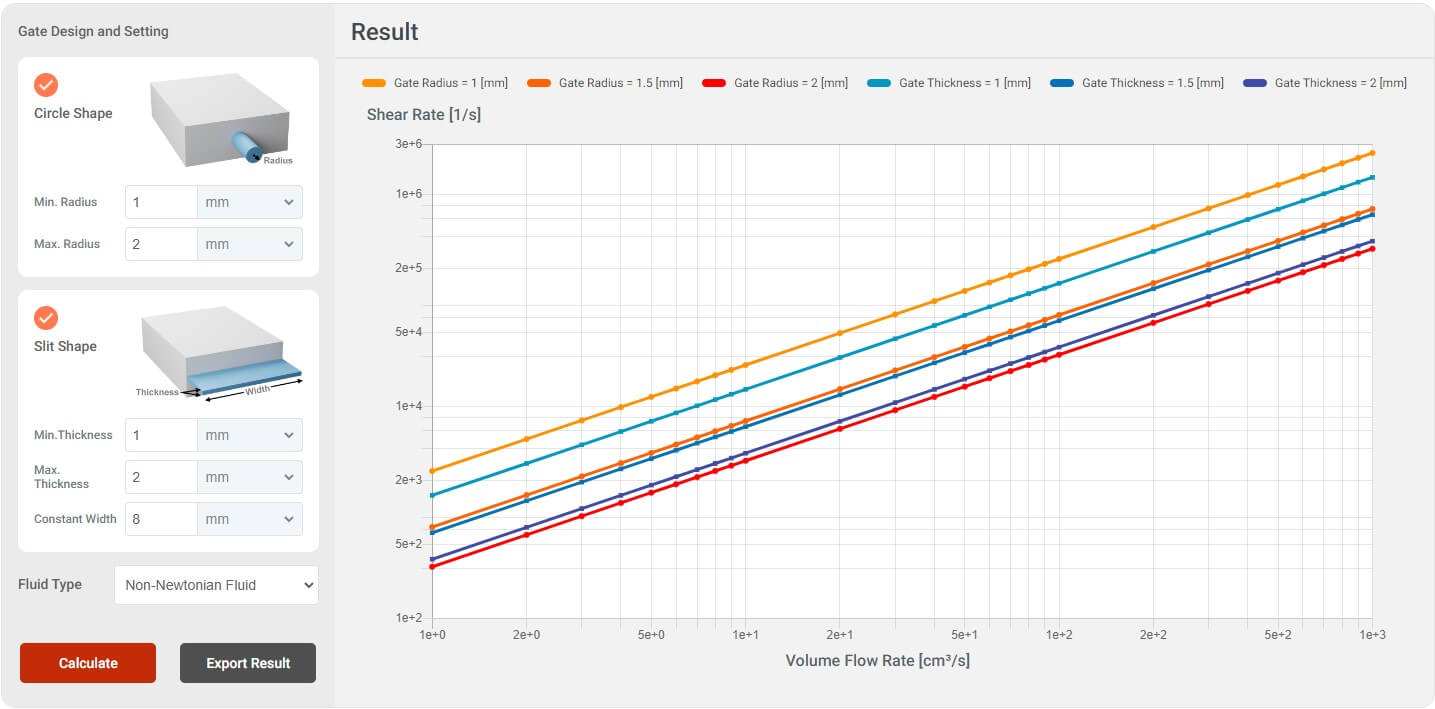

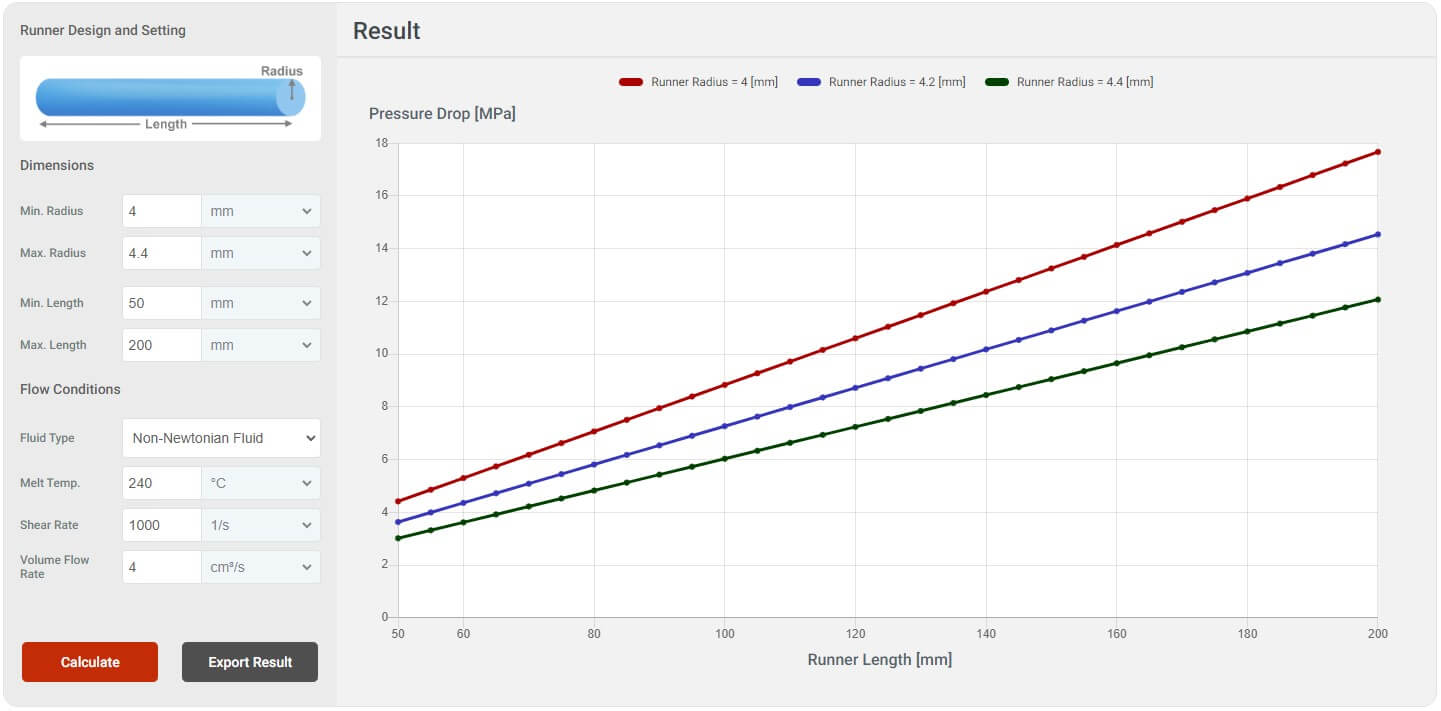

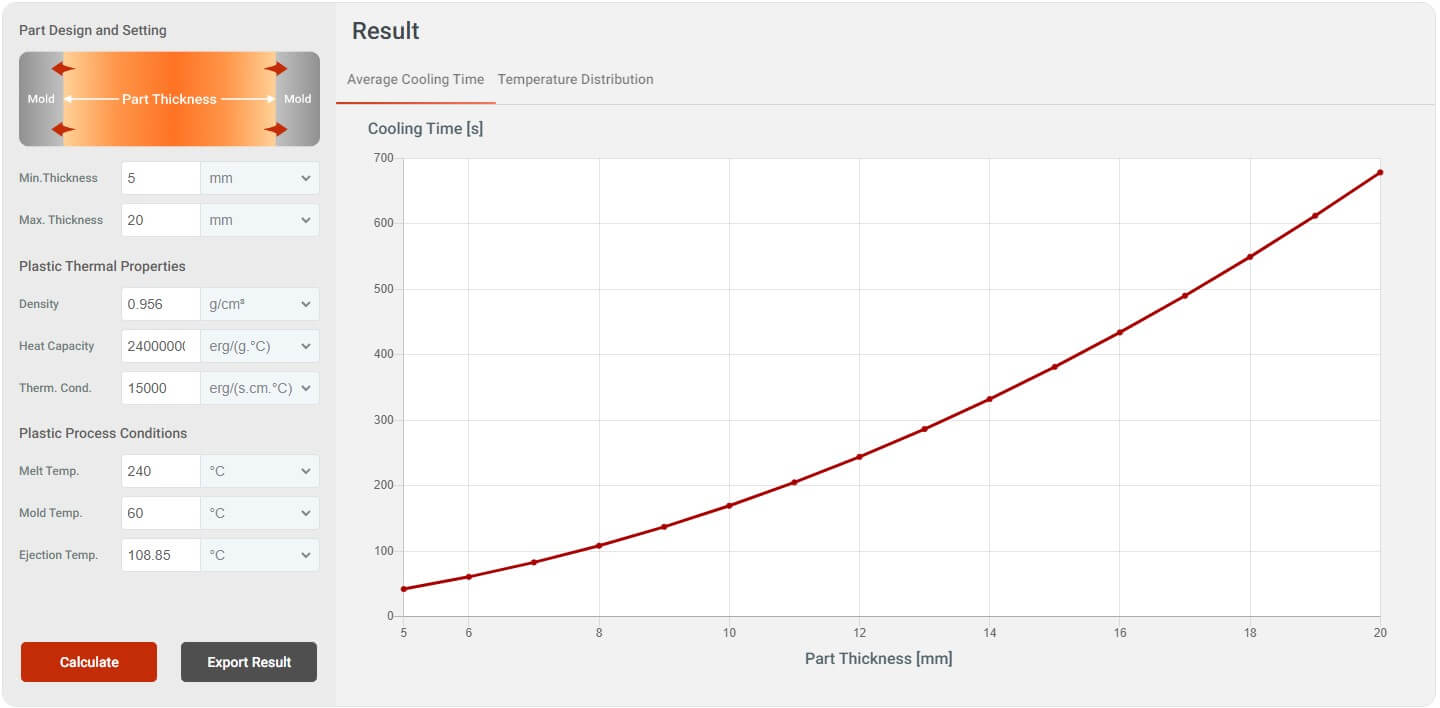

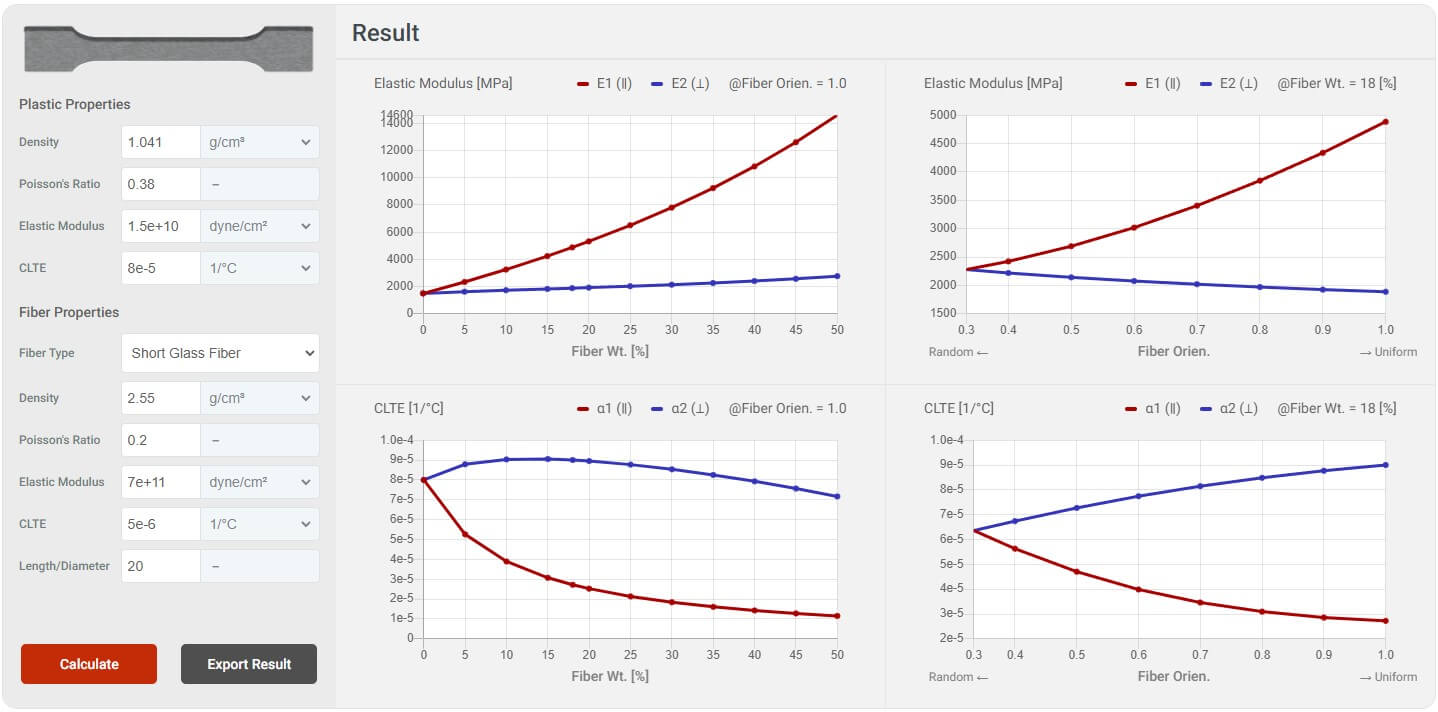

Design Calculator

- Quickly estimate gate shear rate, runner pressure drop, plastic part cooling time and more

Alternative Material

Quickly provide alternative materials and the similarity analysis with user-defined criteria

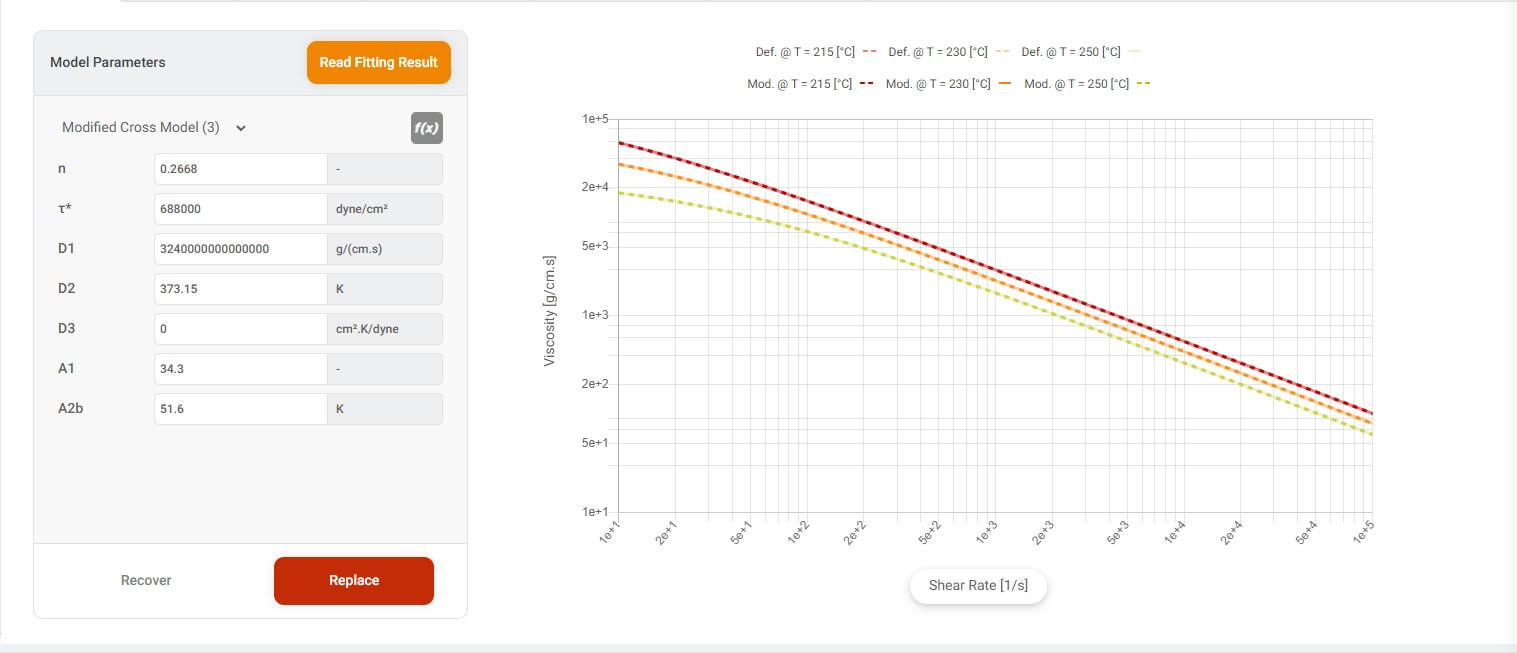

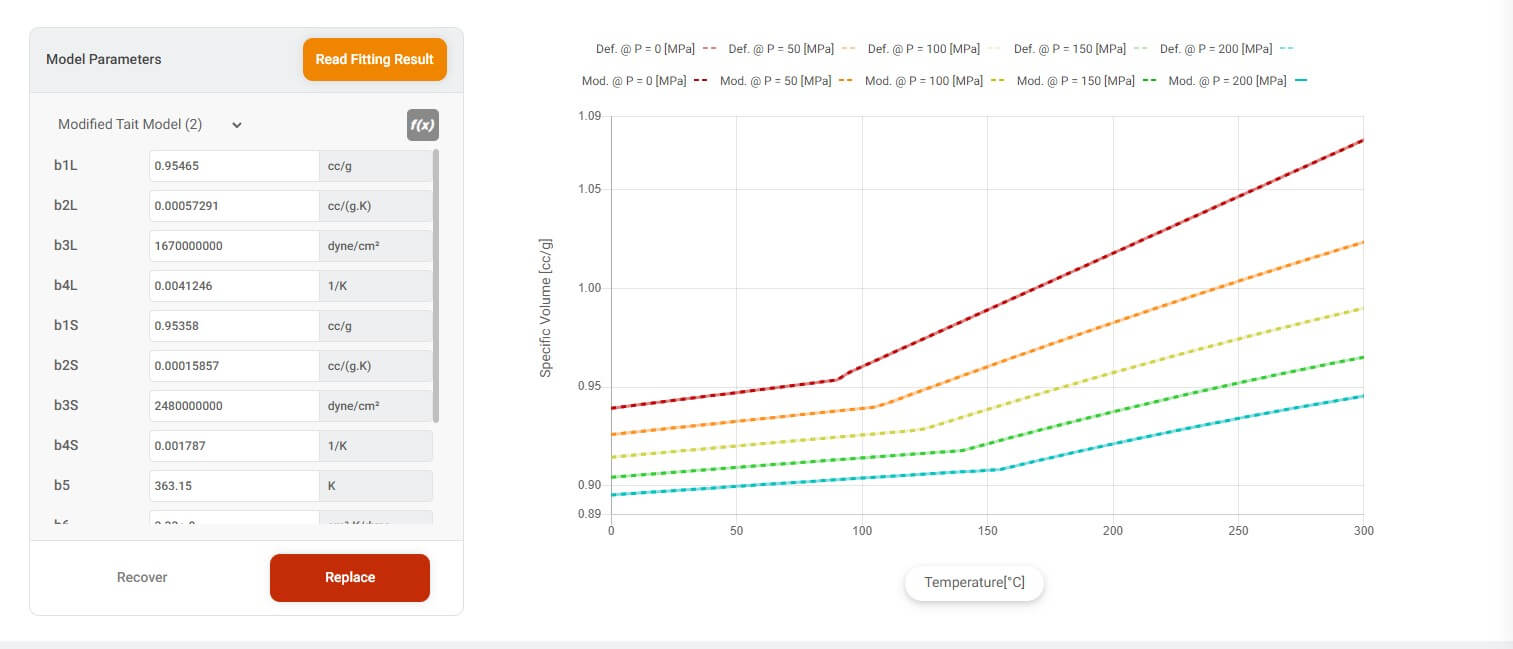

Material Data Fitting

Easily upload material raw data for automatic fitting model parameters

Material Selection Guidance

Suggest good material selection for specified product and part designs with the related information

Digital Material Generator

Conveniently generate material file for Moldex3D simulation

Material Comparison

Compare between different materials with property curves/data and scatter plot analysis

Supplier Data Platform

Suppliers can upload their own material data at any time to update MHC databank

Instant Access with Web Browser

Just log in Material Hub Cloud with web browser and enjoy the whole new experience and a variety of data and information.

Up-to-date Material Database

Continuous and real time update for new product in market to the database, so that you can always get the latest plastic material information.

Exclusive Material Library

Add the favorite materials to your database to manage and download them at any time and any place.

Convenient Functions

Product material and alternative material suggestion, material property comparison, measurement data fitting, material file generation and other convenient functions to assist you in material selection and simulation.

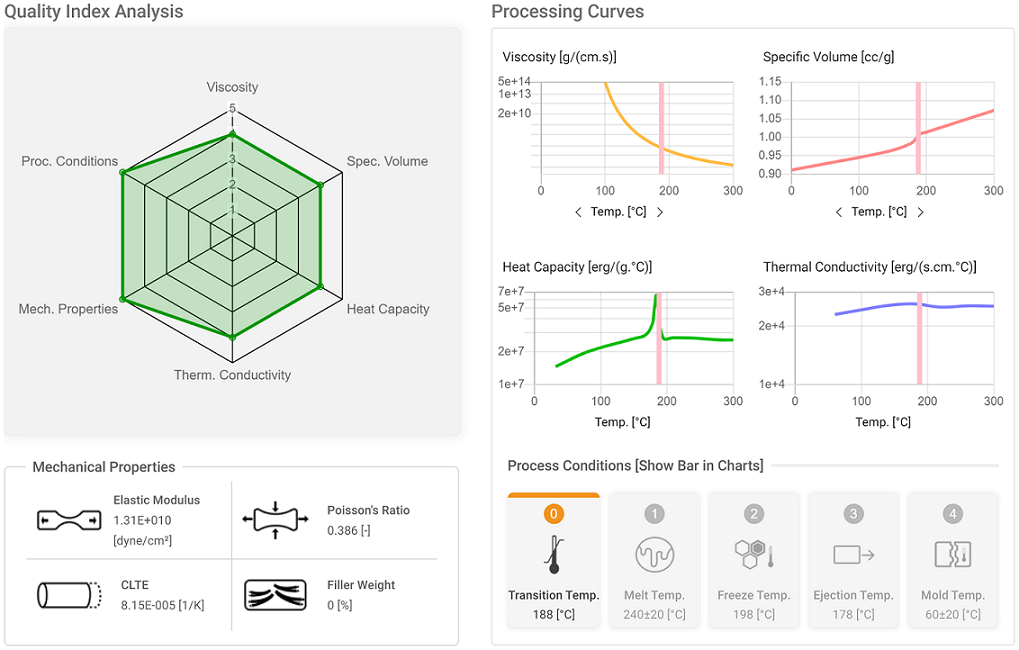

Material Database Viewer

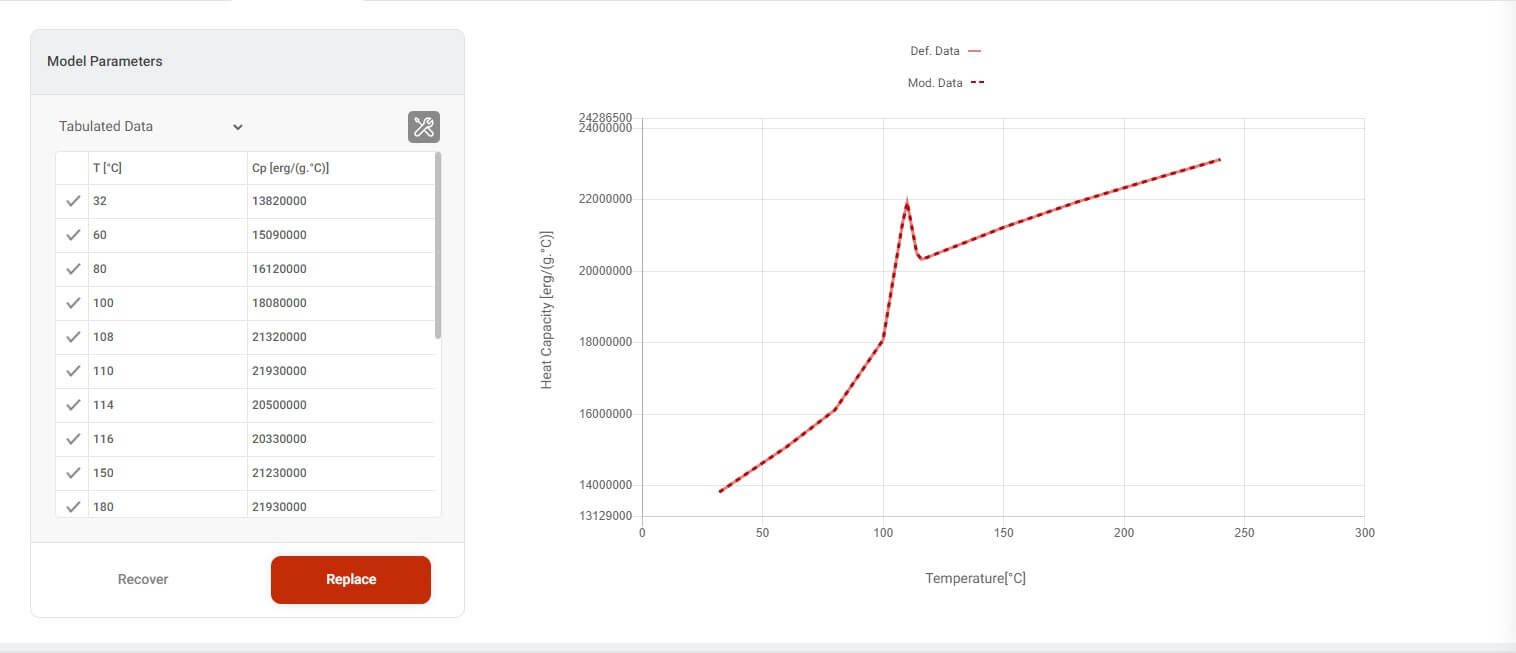

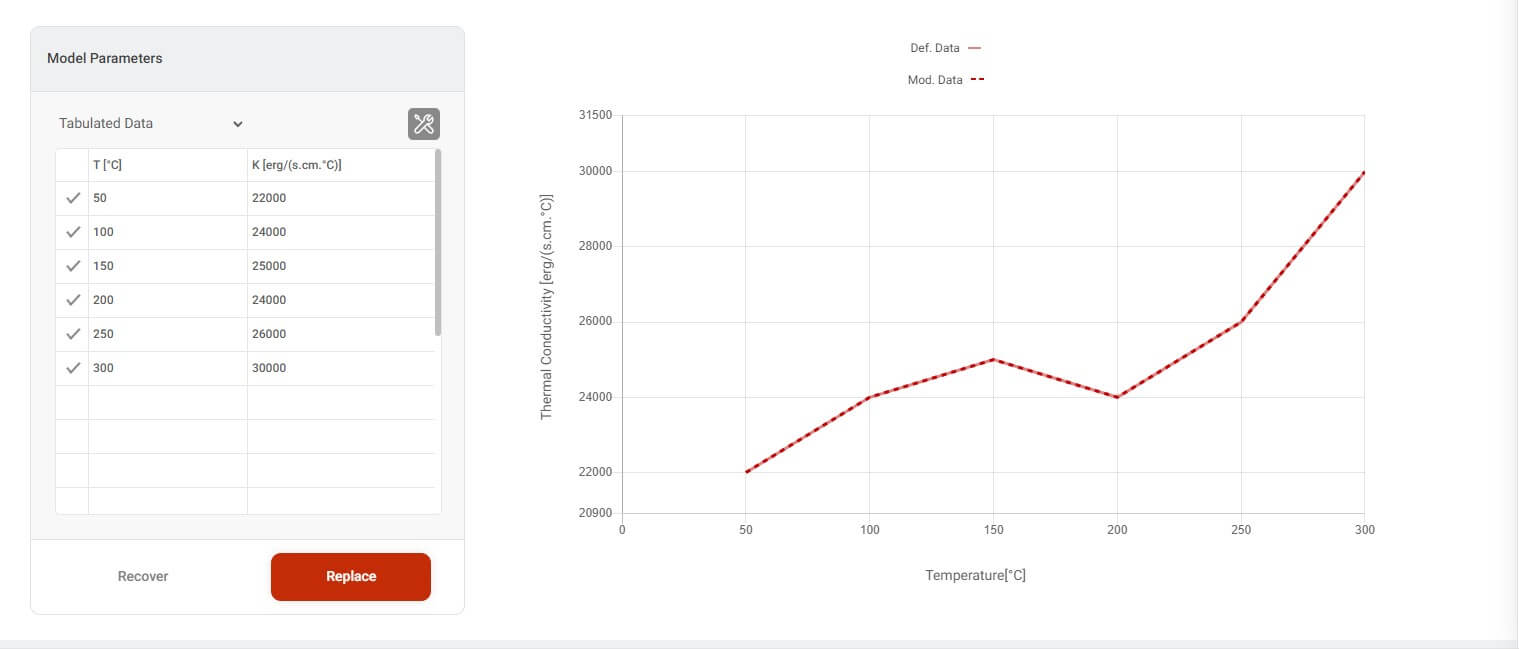

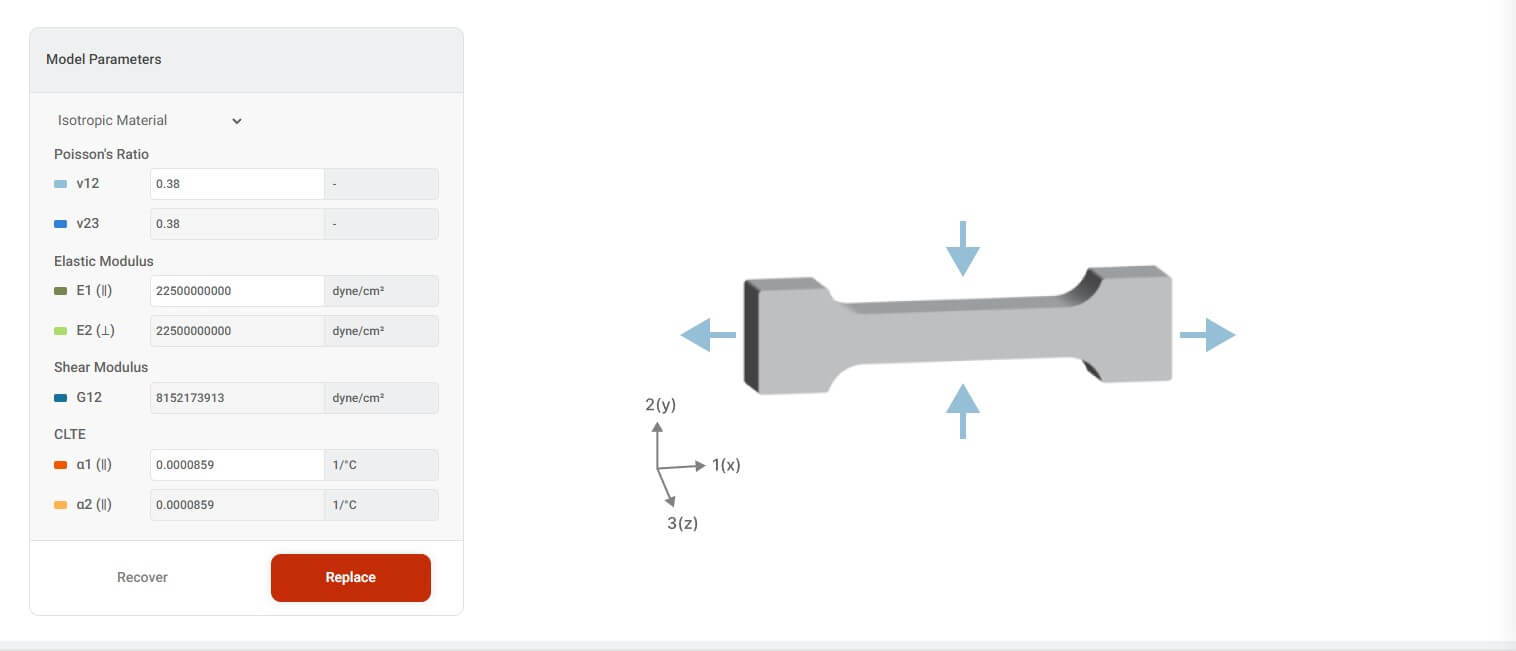

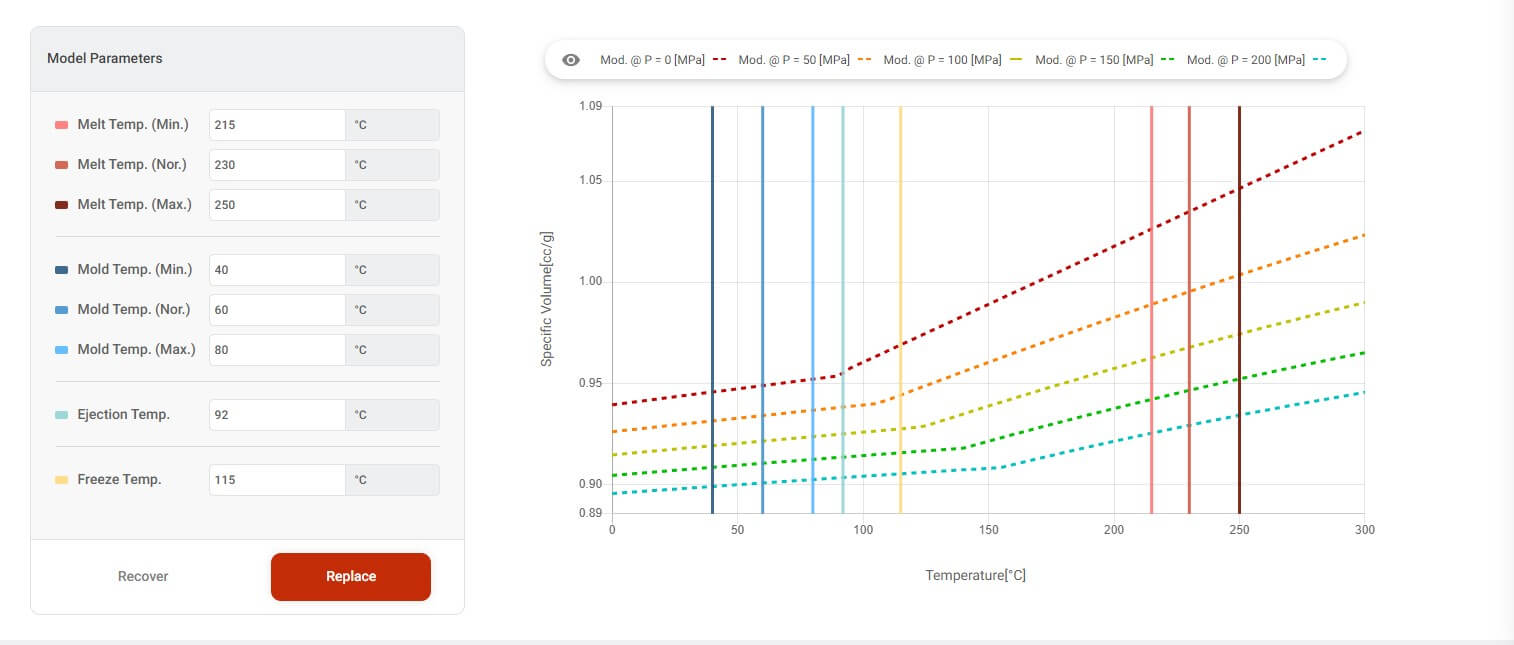

MHC runs strict inspections on every characterized material to ensure each has the accurate information, such as individual physical property inspections, multiple physical property cross-checks, criteria definitions, etc. It also allows users to check plastic mechanical properties, processing curves, and process conditions to learn more details.

Material Database Viewer

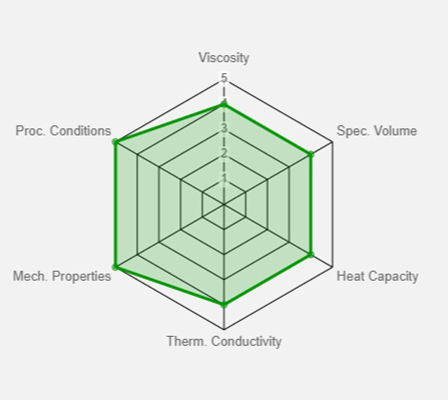

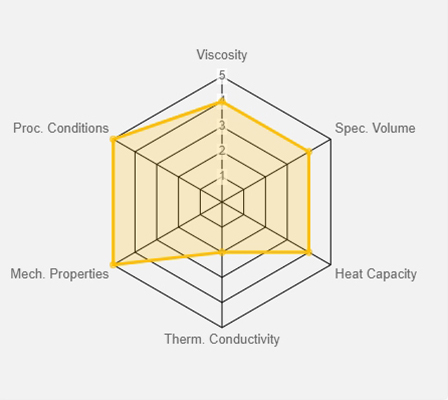

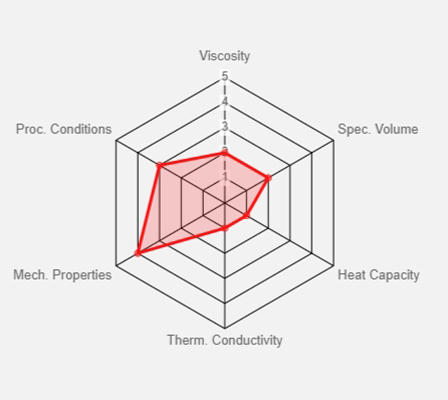

Material Quality Index

The MHC data quality is measured by integrating data sources, measurement methods, and data compatibility for six key physical properties. A Quality Index is provided for each material grade allowing users to quickly evaluate materials, saving time on early design decisions while gaining confidence in the simulation accuracy.

Material Quality Ranking:High Score:over 80%

Material Quality Ranking:Average Score:60%~80%

Material Quality Ranking:Low Score:below 60%

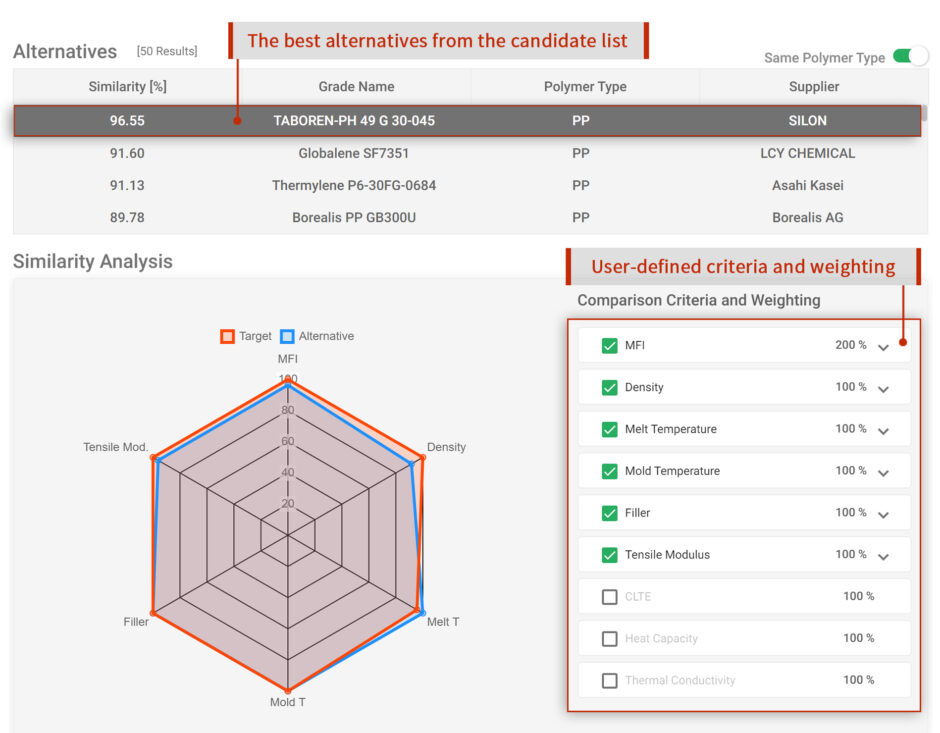

Alternative Material

Select the right material in the design phase is crucial to reduce the failure rate in production, while finding alternative materials is key to maintain mass production speed. To achieve these goals, MHC helps you find a list of alternatives by defining physical properties or processing conditions. You can also determine the best alternative material by running similarity analysis.

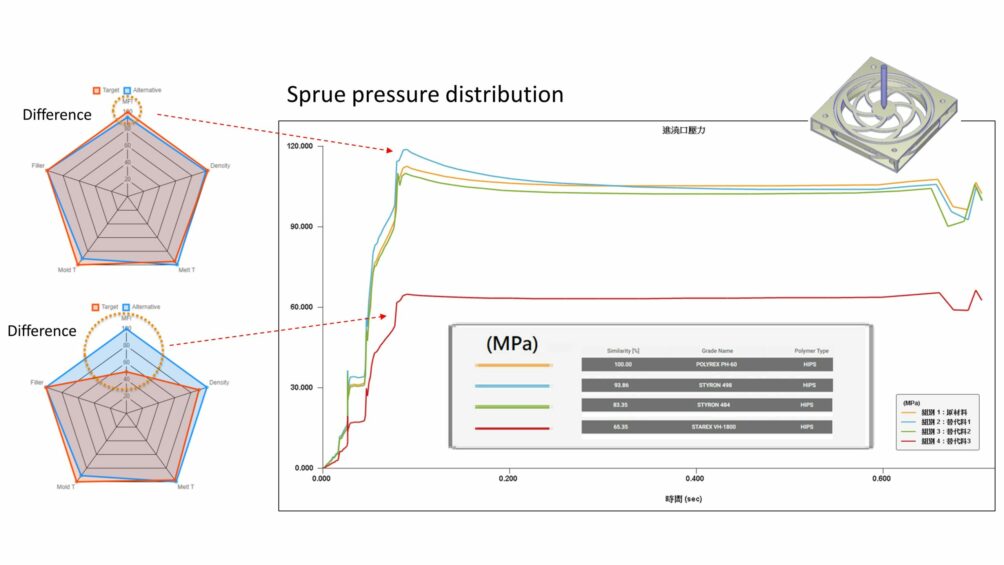

The examples below are three alternative materials picked out by Alternative Material Function in similarity analysis to carry out Moldex3D simulation. From the distribution result of the sprue pressure, the least similar material has the biggest pressure difference compared to the original material.

The examples below are three alternative materials picked out by Alternative Material Function in similarity analysis to carry out Moldex3D simulation. From the distribution result of the sprue pressure, the least similar material has the biggest pressure difference compared to the original material.

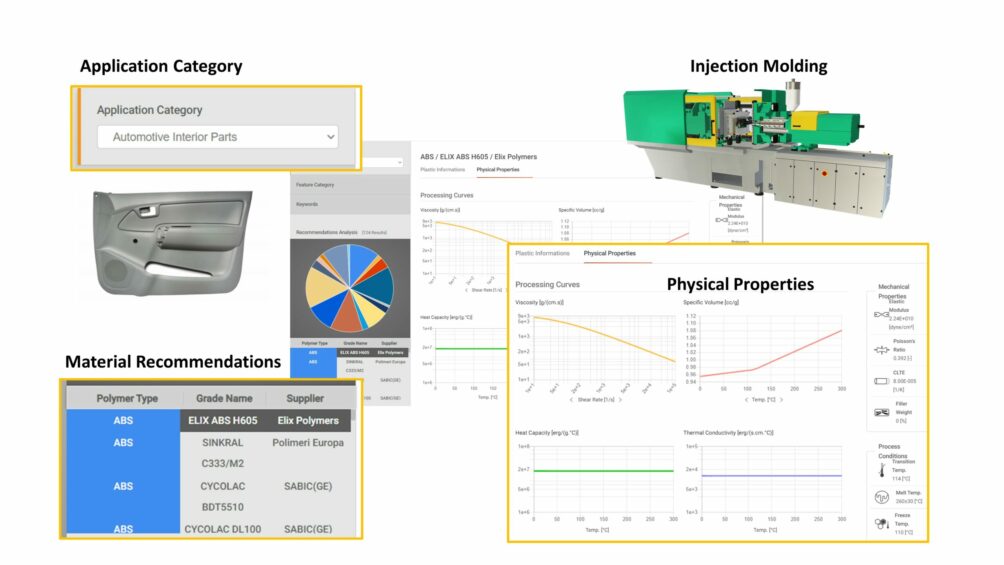

Material Selection Guidance

There are nearly 10,000 plastic materials on the market. How do you find the right one? MHC filters out suitable materials based on the product industry and characteristics. With MHC, finding the perfect material will no longer be a needle in a haystack.

Material Comparison

Quickly compare the properties of multi-materials with curves and side-by-side data. The scatter plot visualizes the relationship of user-selected material to others.

Supplier Data Platform

Seamless new product information sharing between customer and supplier. Suppliers can upload their up-to date material data at any time to MHC databank and exhibit new products to user.